Exploring Emergency Stops - All you need to know

Emergency stop switches, also known as E-Stops, or kill switches, are fail-safe switches used to reduce the risk of injury by stopping machinery quickly. E-Stops are found in most industrial and commercial environments. They are used anywhere where you will find large machinery. E-stop buttons can also be found in public environments where there may be risks, for example, escalators and fuel dispensing bowsers.

Emergency stop buttons are fitted for easy access in any emergency. E-Stops are red and must feature a yellow background, bezel, or housing for attention, and may be labelled. The button is designed to be operated easily, even with gloves. They may also light up for use in darker environments.

There is a range of emergency stop buttons available for different applications.

Emergency stop switches break an electrical circuit to prevent power from passing through. This causes the machinery to stop functioning immediately.

E-stop switches are designed to be easy to use and avoid any confusion in high-pressure situations. E-stop are typically red, and are bright and instantly recognisable, while the button itself is shaped for easy use.

The physical placement of your emergency stop button is important to consider. It must be installed in a location which is obvious and easy to reach.

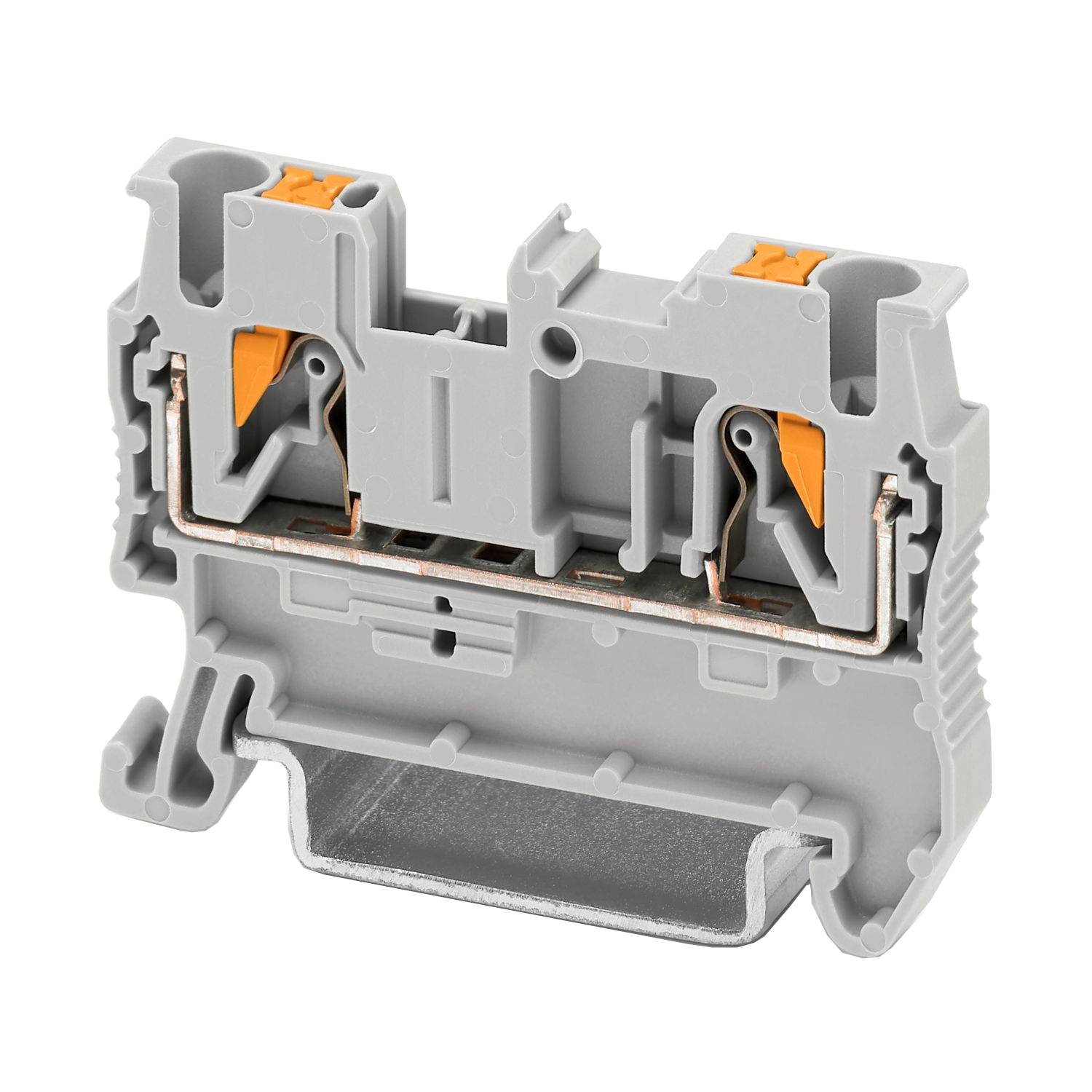

When it comes to wiring your emergency stop button, it will sit within an electrical circuit to allow the current to pass through the button. It will usually be before the control breaker and after the standard on/off switches.

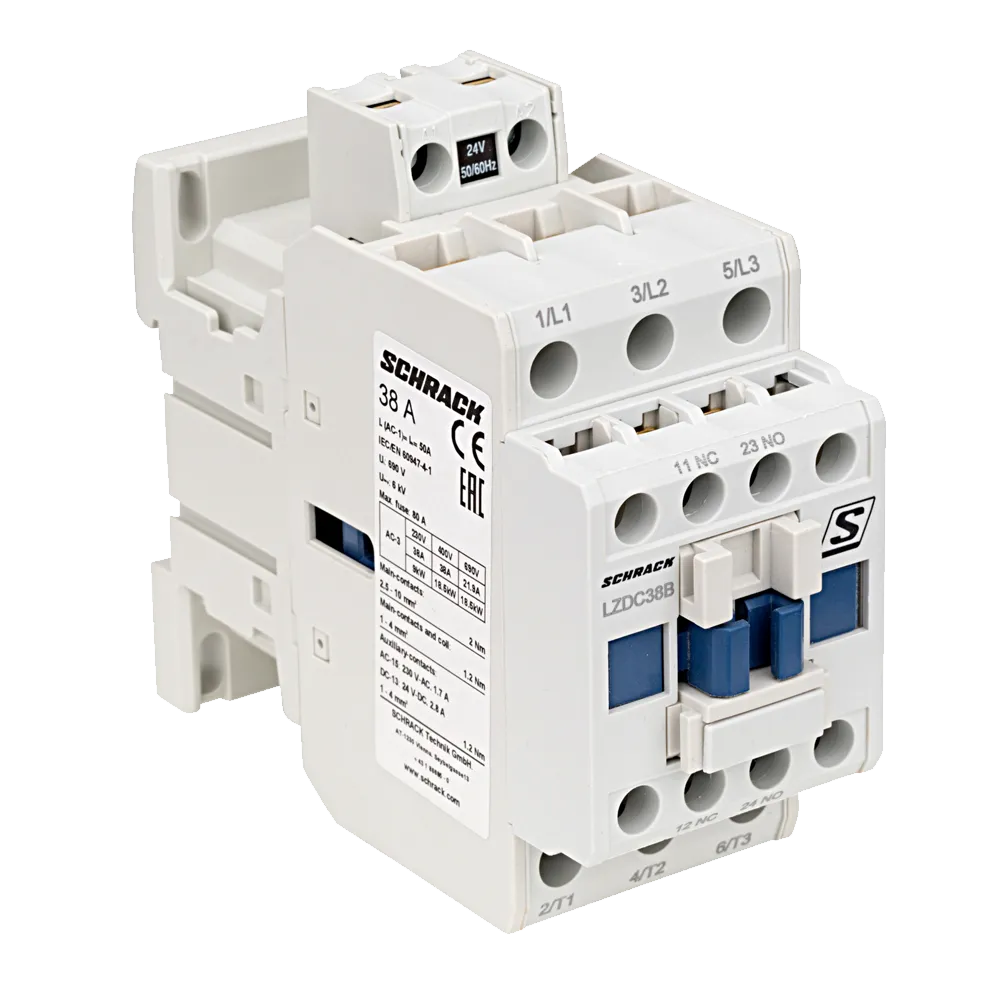

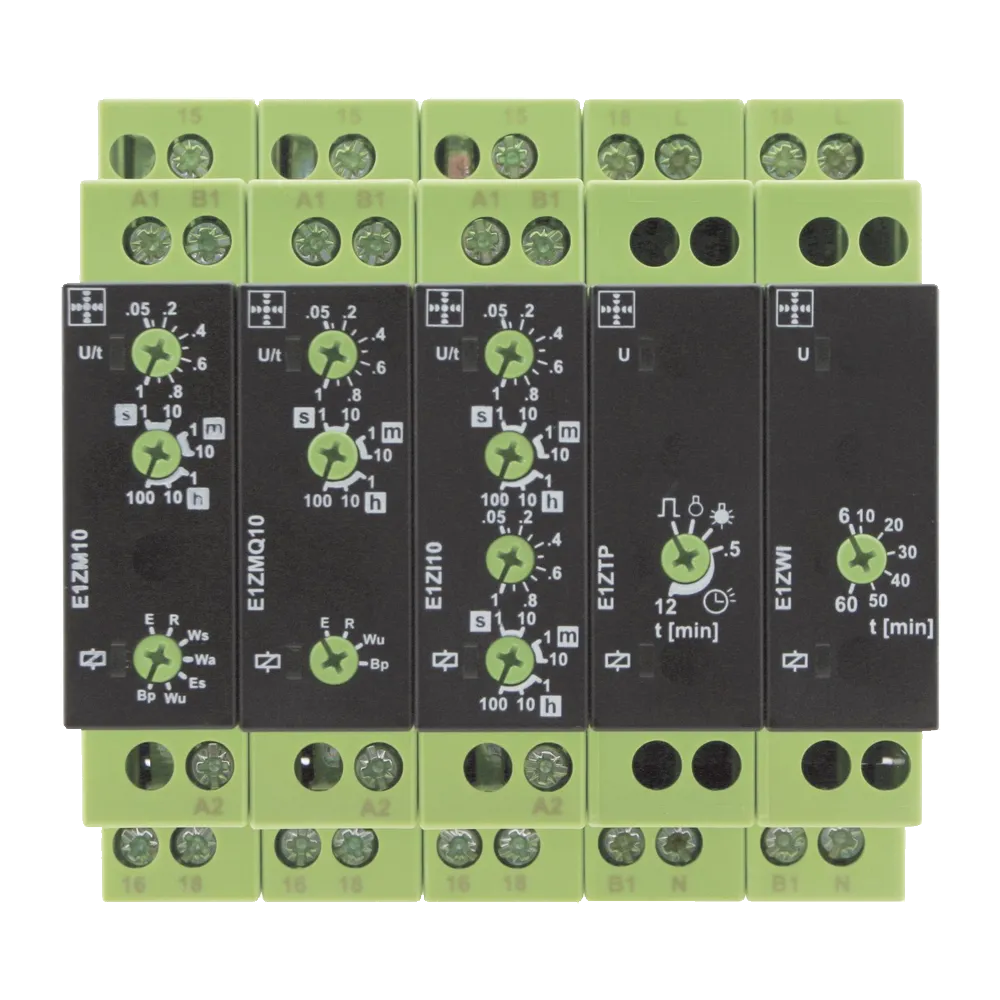

Emergency stop buttons are typically used with two Normally Open (NO) contacts. They are used to unlatch the control relays. For other signalling functions, you can attach additional Normally Closed (NC) contacts.

NC (normally closed) contacts are closed, and they open on operation

NO (normally open) contacts are open, and they close on operation

Panel Mount

Surface Mount

Resetting Emergency Stop Switches

Pull to release – this is a common type of button which is simply pushed to activate. It is then pulled back outwards to release.

Twist to release – Similar to the push/pull, this button is pushed to activate. To release, the button is twisted

Key release – this button is also pushed to activate but must be released using a key. The key is inserted into the head of the button. The key release is ideal for ensuring authorised operation in high-risk environments

E-Stops should never be covered as they are required to be quickly and easily accessible in an emergency. They can however be guarded as to protect against accidental activation.