Horticulture & Livestock Lighting

An artificial light that simulates natural light

Over the last 50 years our habits have changed. Today the food sector finds itself having to respond to an ever-increasing demand for out-of-season fruit, vegetables and greens, as well as a greater quantity of meat and fish, to meet the needs of a world population close to 8 billion.

It is not surprising, therefore, that the number of indoor farms and crops has also increased , where it is possible to grow plants and animals in a constant and controlled way, thanks to technological solutions that simulate the external environment.

In this context, lighting engineering plays a fundamental role in guaranteeing the right amount of artificial light, and the connectors become the fulcrum of efficient and modular lighting systems, capable of providing internal spaces with light that is almost identical to natural light. Both the light bodies and the connectors, however, must meet technical requirements that make the systems safe and long-lasting, and it is only with in-depth knowledge of the sector that concrete answers can be given to the needs of indoor farming, vertical greenhouses and intensive cultivation.

Techno solutions for horticulture and livestock farming

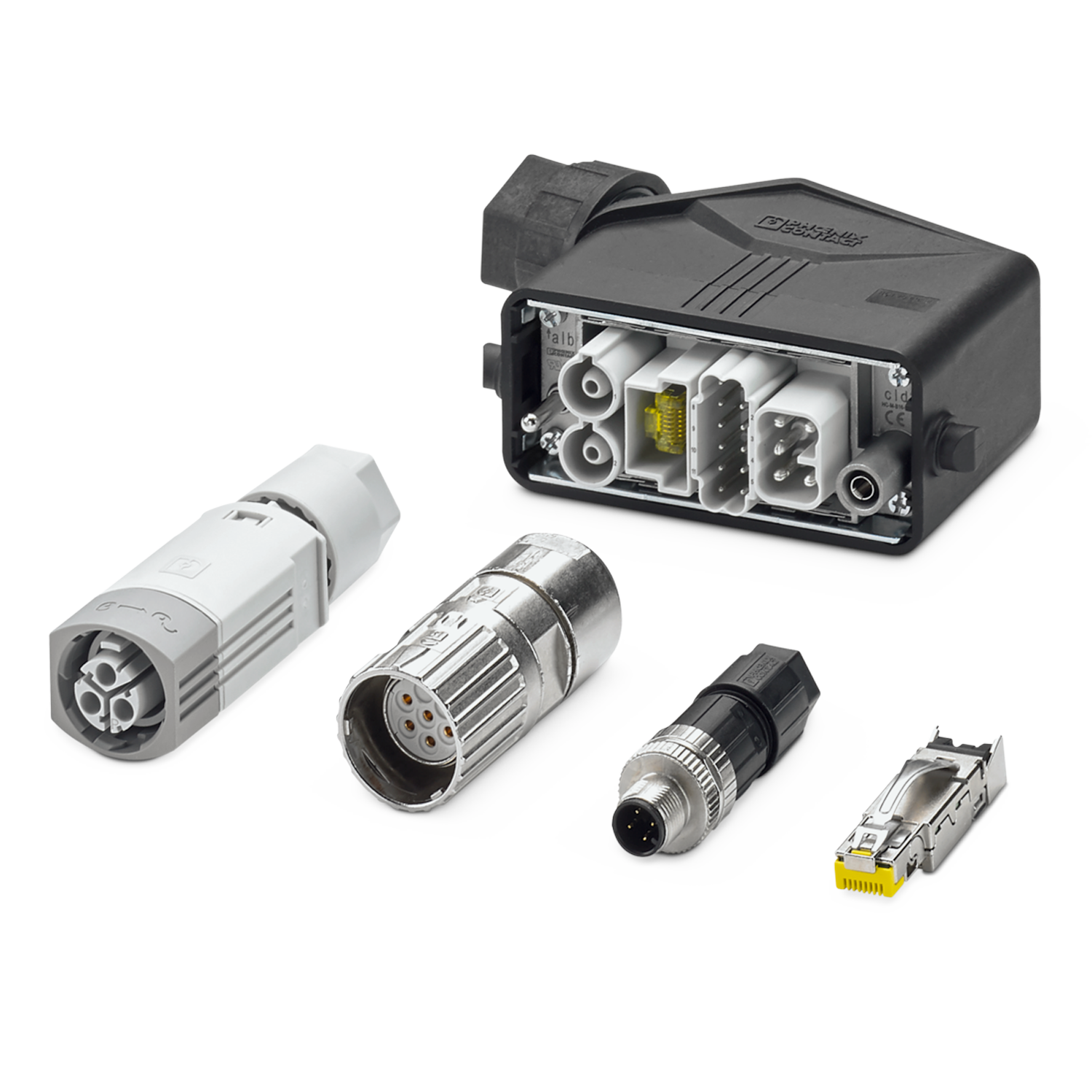

For over 30 years we have been designing and manufacturing connectors that support the lighting sector in the creation of specific solutions for each application sector. The collaboration with specialized engineers and biologists allowed us to identify the needs of farmers and breeders, and to study connectors that could be easy to install and wire, but also resistant to traction and water jets.

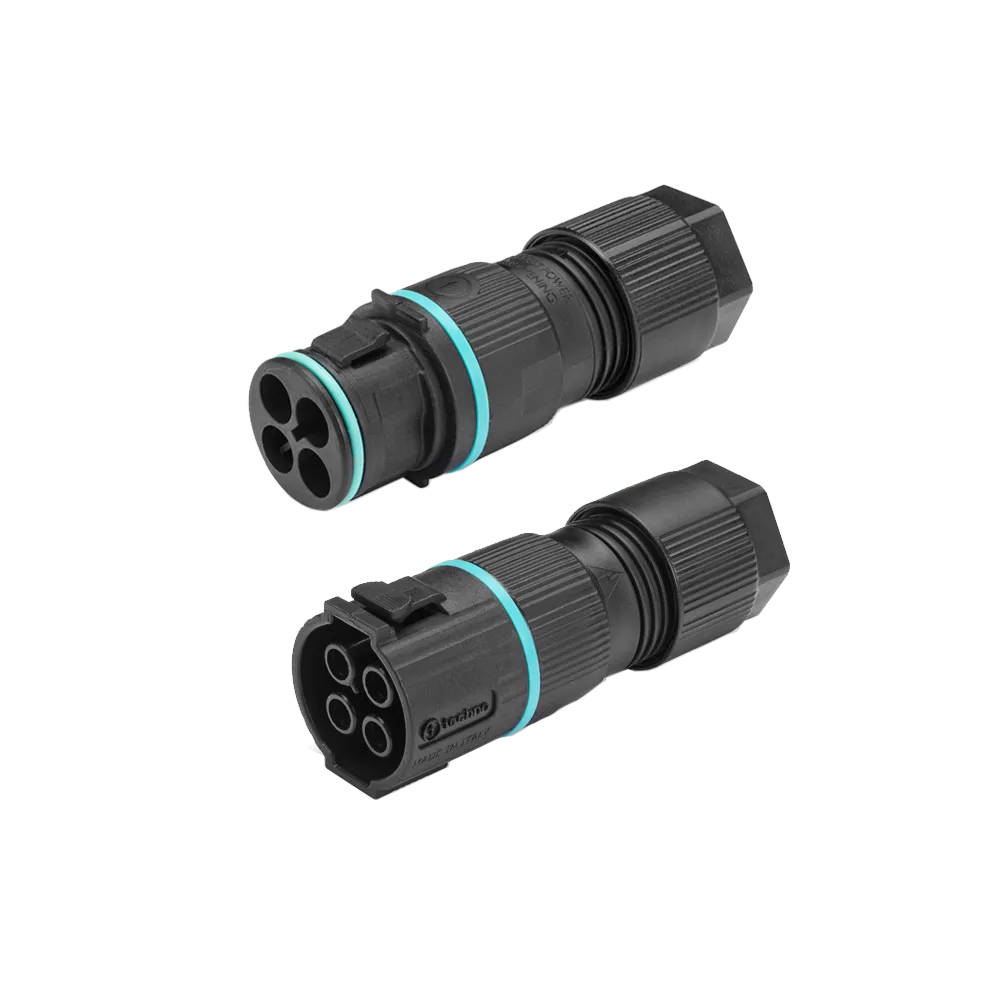

Thanks to our technical expertise, manufacturers of lighting systems can therefore count on secure connections , with Easy-click and anti-tamper systems, which make each system more efficient even in difficult environments , such as greenhouses with high levels of humidity, underwater systems and vertical greenhouses.

Connectors and systems for every situation

Fishing industry

In fish farming, light affects both the health of the fish themselves and the growth possibilities of the eggs and larvae. With LED systems equipped with connectors resistant to humidity and contact with water, it is possible to recreate artificial lighting that reduces the stress of individual animals and improves their quality of life.

Poultry farming

Hens, chicks and chickens perceive light differently than humans and are disturbed by even the slightest flickering or small changes in light intensity. Lighting systems for poultry farming must therefore maintain a constant diffusion of light and reproduce solar cycles with the utmost attention.

Horticulture

Horticulture in traditional greenhouses or vertical greenhouses must respect the production times required by the market, which are often different from the natural growth needs of the products. Thanks to solutions designed specifically for this sector, it is possible to grow vegetables throughout the year, but also to improve the nutritional intake and shelf-life of each product.

Decorative spaces

Lamps for horticulture and livestock also find application in buildings that want to recreate natural environments inside them. This is the case of hotels, spas, cruise ships and spa centers where the green component makes the spaces more harmonious and relaxing, but to grow and flourish luxuriantly it requires the right amount of artificial light.

The benefits of effective lighting for horticulture and livestock

Light is the engine of the agricultural sector. With the right amount of light, you can grow vegetables, fruit and greens throughout the year, speeding up the growth of plants, improving their nutritional values and extending their shelf-life. Furthermore, in the livestock sector, light improves the health of animals, promotes their growth and increases the chances of survival of eggs and larvae.

In horticulture and indoor breeding, where often the only source of light is artificial, to obtain real advantages and increase results in terms of quality and quantity of production, the lighting systems must simulate the natural light of the Sun.

Manufacturers of horticultural and livestock systems are therefore called upon to design and implement solutions that respond to the technical needs of the sector and positively influence the production growth of agricultural companies.

The technical needs of lighting for agriculture and livestock

Flexibility

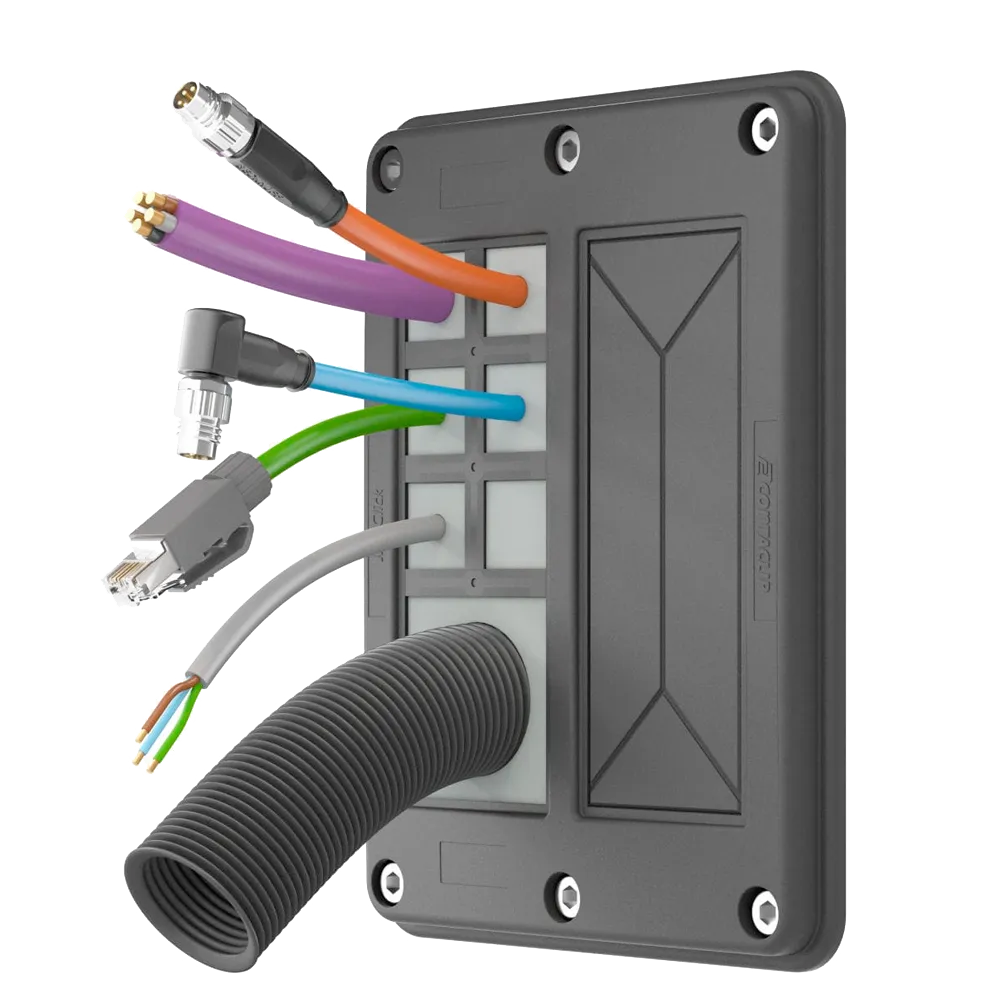

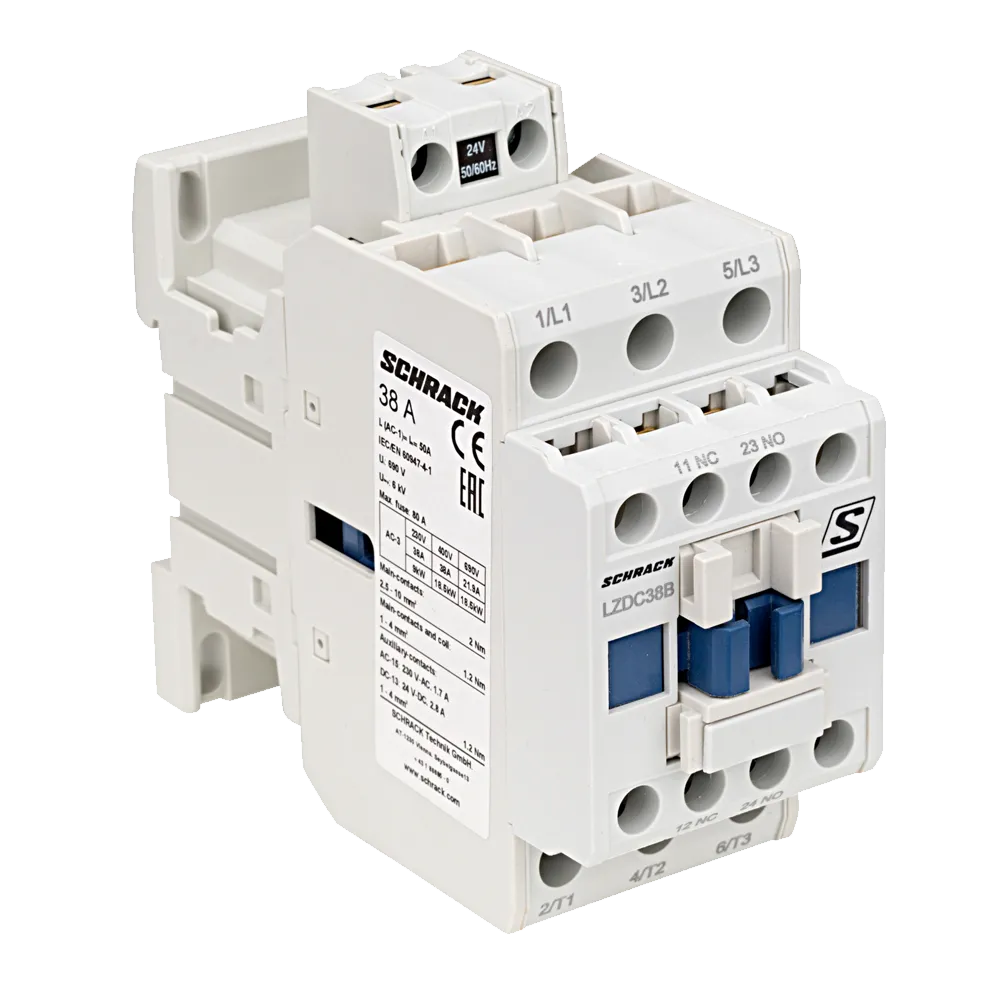

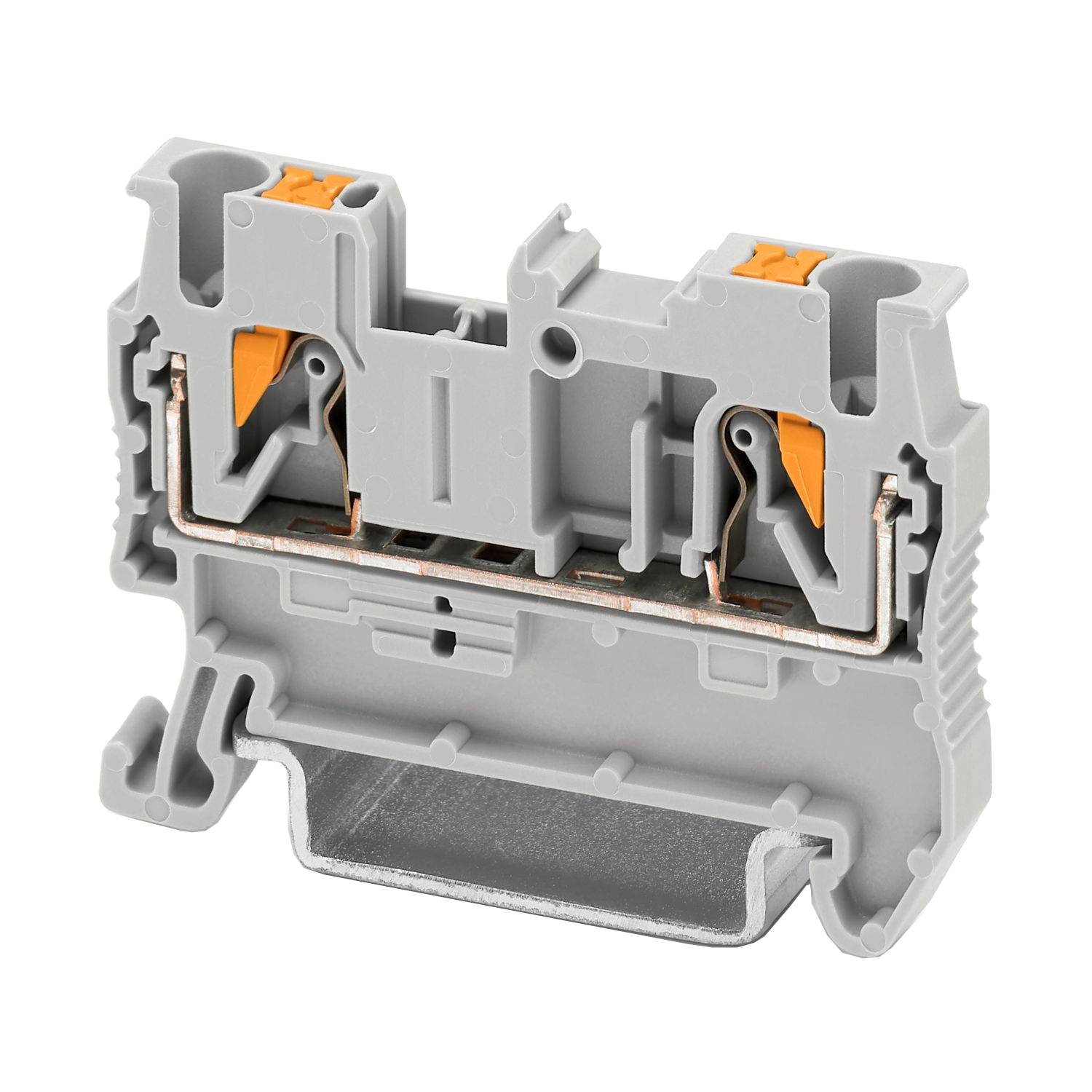

Within horticultural farms and greenhouses, needs are constantly changing, which is why there is a need to have modular systems that the user himself connects and disconnects as needed. The use of easy-click connectors that facilitate wiring and prevent accidental disconnection, intuitive cable glands and spring systems are essential prerogatives for creating effective lighting systems that are easy to manage over time.

Moisture resistance

In the agricultural sector, the humidity level is as important as the supply of light. The connectors present must be insulated and resistant so as not to jeopardize the correct functioning of the entire lighting system and to last over time without the need for extra-ordinary maintenance and continuous replacements.

UV resistance

In outdoor environments, UV rays can ruin lighting systems just as much as rain and frost. Headlights and connectors must be certified to resist even high temperatures without deforming and without compromising the correct functioning of the system.

Series connections

Greenhouses and farms need to be illuminated uniformly and one lamp body is not sufficient. Lighting for horticulture and livestock farming must include systems composed of multiple devices, which can be connected to each other based on actual application needs.

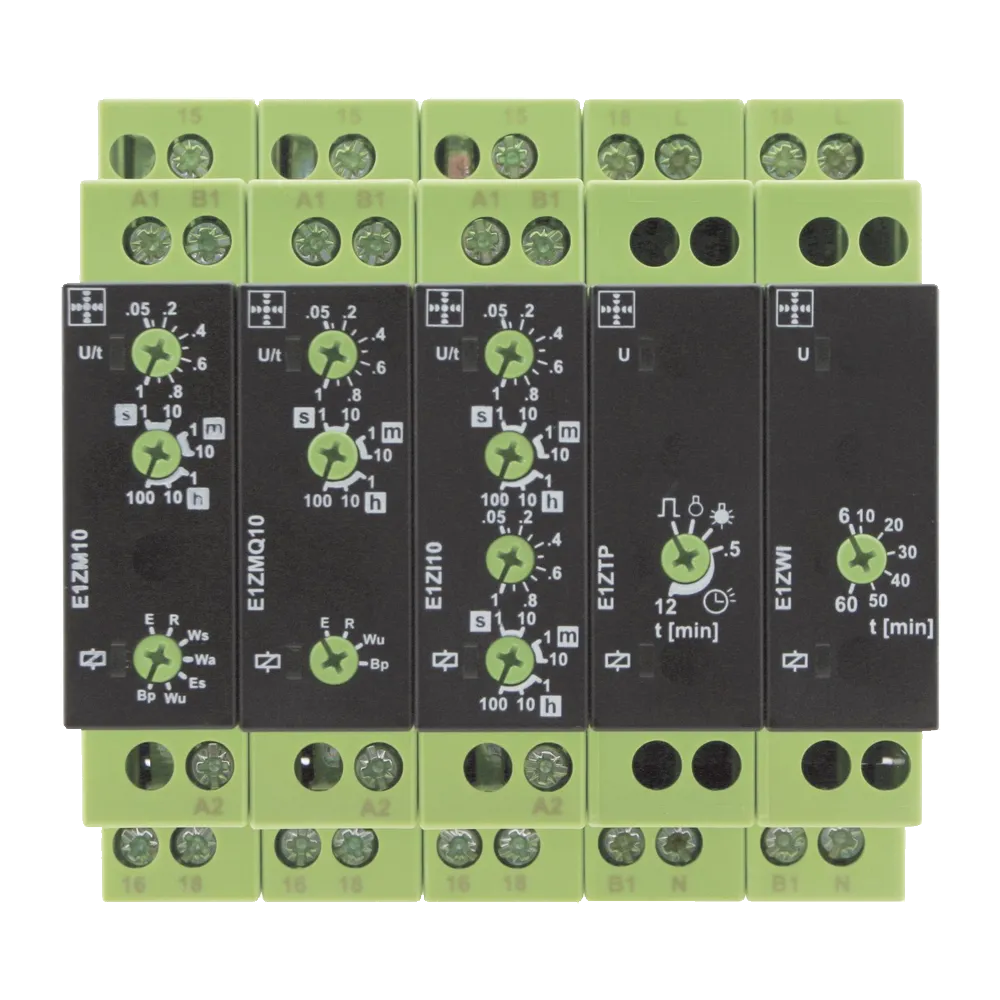

Constant diffusion

Especially in the poultry farming sector, light interference negatively affects animal welfare, which is why it is essential to have systems and connectors that maintain constant brightness and are able to simulate daily and seasonal solar cycles, going from total darkness to maximum brightness without interference.

Easy cleaning

The direct contact between lamp bodies, connectors, plants and animals makes it necessary to constantly clean the system which must be designed to resist chemical components for longer than other solutions in the lighting sector.

Reduced heat

Heat also affects the growth of plants and animals. Both on farms and in indoor cultivation it is important to maintain a constant temperature and prevent lamp bodies and connectors from overheating when used continuously.

Anti-tamper systems

In some cases, direct contact between the implants and animals could cause accidental disconnection. Both the lamp bodies and the connectors require anti-tampering systems that ensure their durability over time and prevent sudden shutdowns.

Techno connectors for horticulture and livestock

The connectors we offer for the horticulture and livestock sector are designed to make installation almost immediate. One of our solutions, the push-pull connectors, feature an Easy-click system, where the pressure of a finger is enough to release the connector, while a mechanical bayonet hook facilitates the attachment of the cable gland and guarantees correct installation without the need for special tools. The anti-tamper closure prevents accidental release and resists up to a traction of 25kg, while the innovative spring system speeds up wiring operations and makes it possible to connect the conductors to the terminals in just a few moves.

Connectors tailored to your idea of light

In addition to the production of standard connectors born from the needs of the lighting sector, the technical preparation of our engineers pushes us to face new challenges every day and design connectors tailored to specific application needs.

Don't put limits on your creativity! Design the lighting spaces you want: we'll take care of the reliable connections!

Check out our connectors for sports lighting: