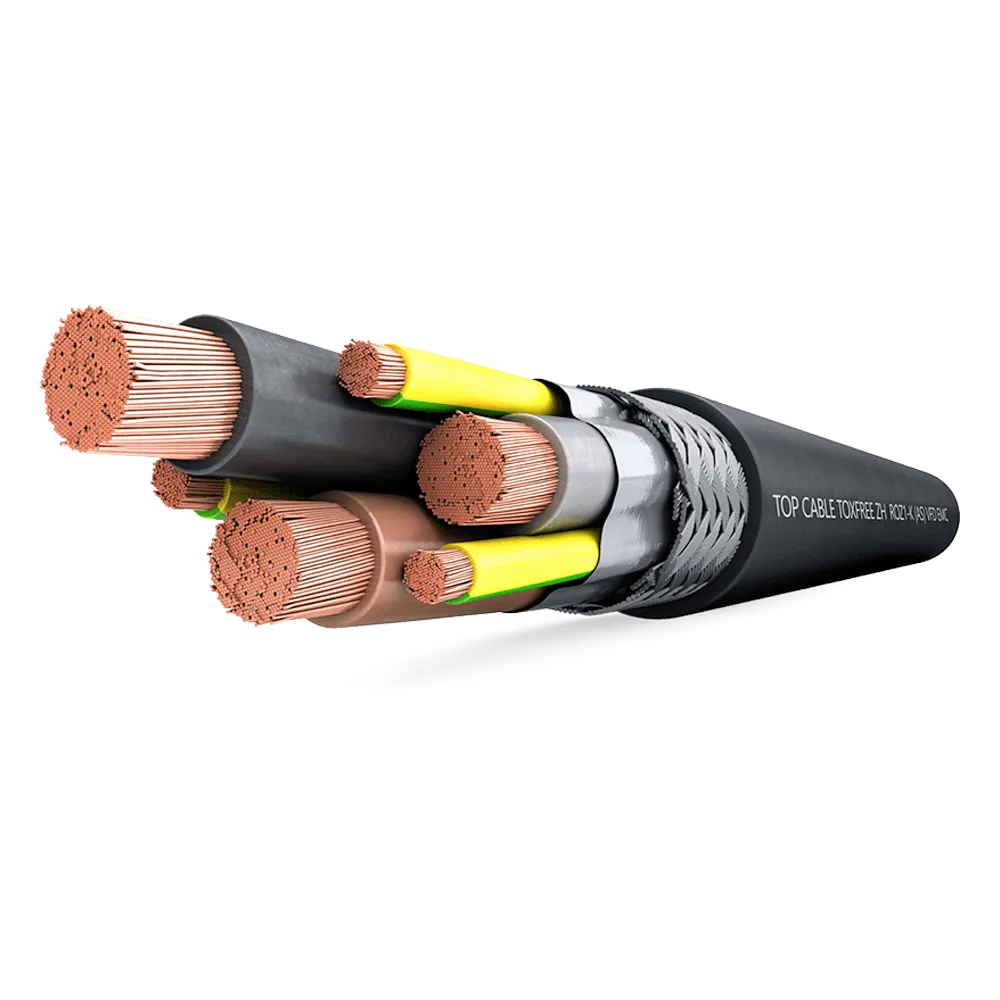

The high performance cables for powering variable frequency drive (VFD) motors feature a symmetrical 3 core + 3 earth configuration (in the larger conductor sizes) and double shielding for 100% coverage, with a halogen-free outer sheath, providing maximum system reliability and stability. cable has been specially designed for industrial VFD installations where it is necessary to limit the effects of Electromagnetic Interference (EMI).

Recommendations for selecting the right VFD cable

25% of the world’s electrical energy is consumed by electric motors. Variable frequency drives (VFD) provide better performance and increased energy efficiency for industry but, at the same time, one of their main disadvantages is the emission of electromagnetic interference. To limit interference it is necessary to use equipment and cables with electromagnetic compatibility, known as EMC.

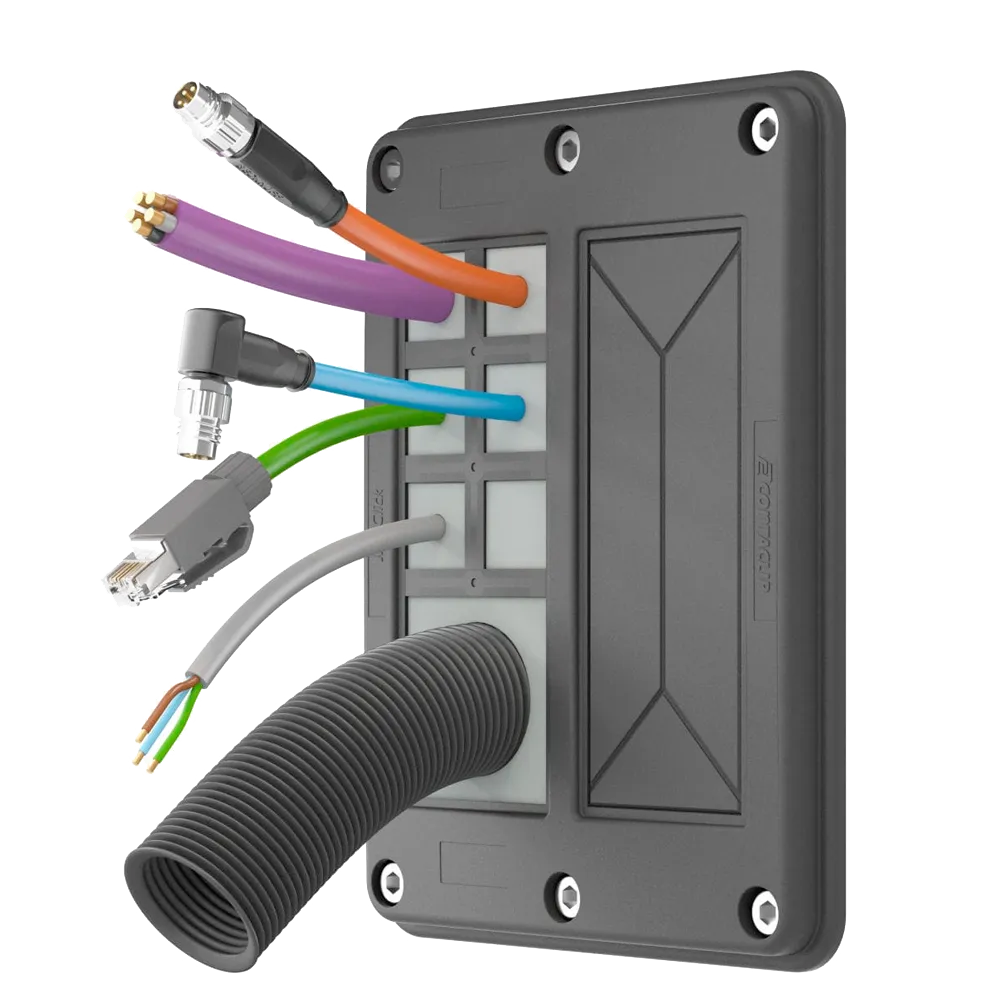

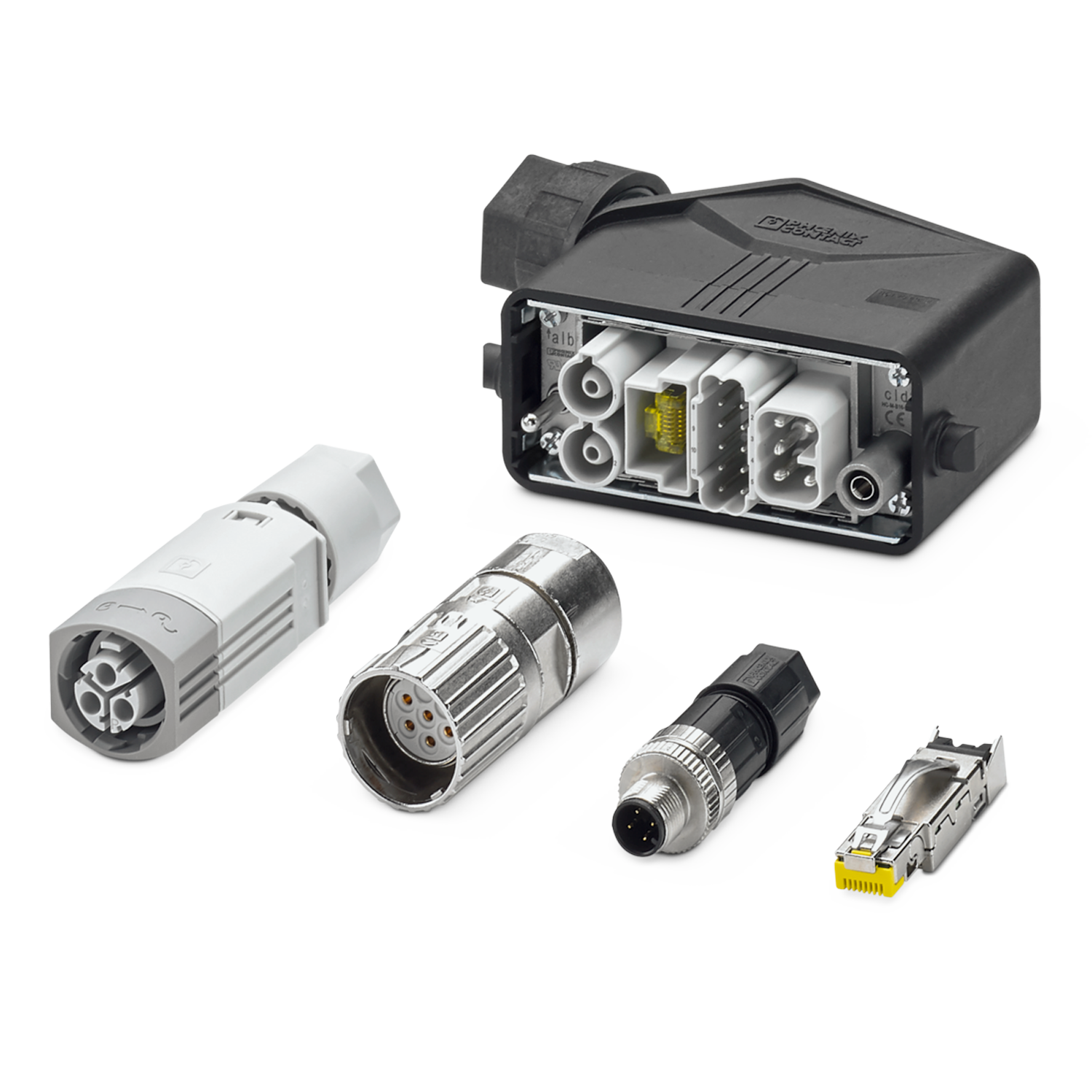

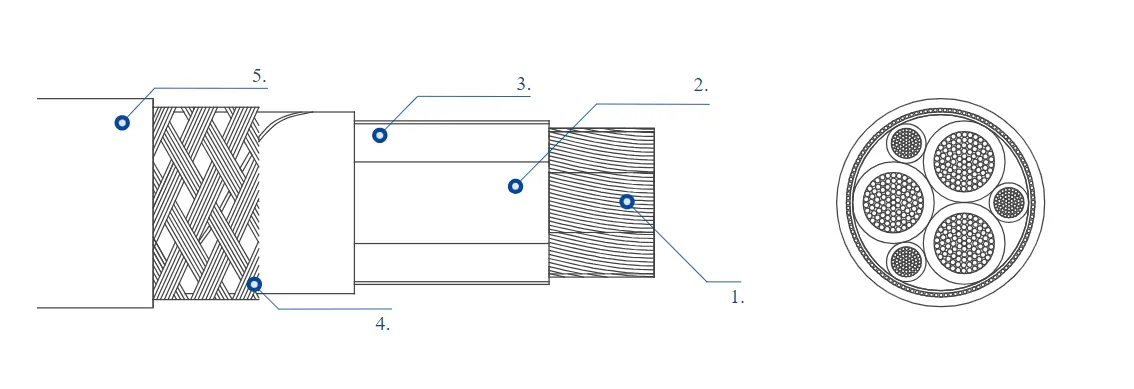

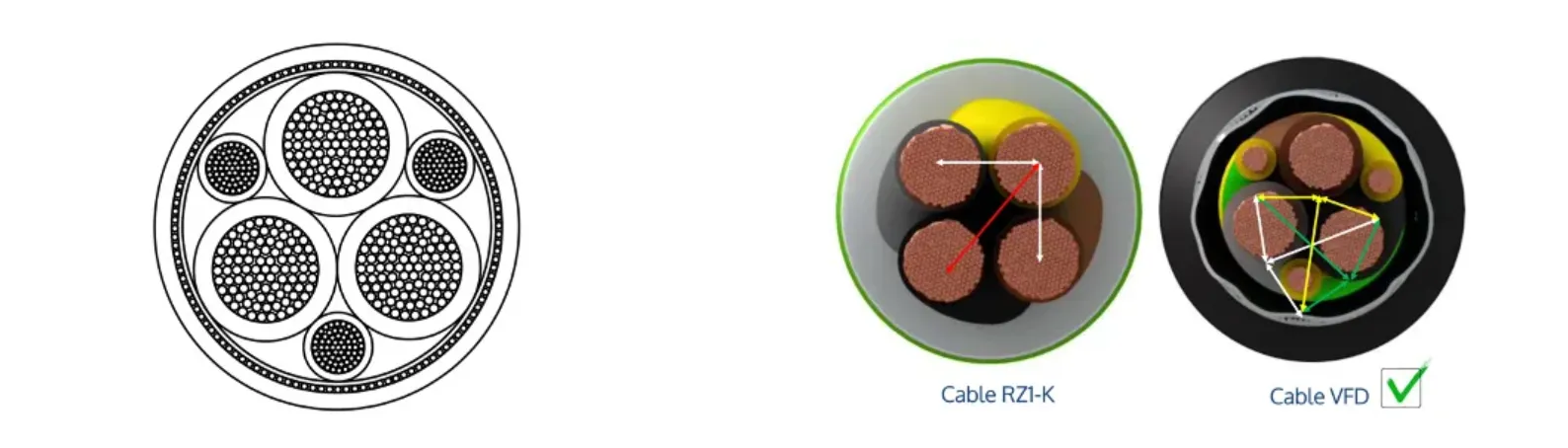

EMC is achieved in an electrical cable by two features: first, through a symmetrical distribution of conductors. Secondly, by adding a shield to ensure protection when using VFD motors.

To improve the performance of the VFD, we therefore recommend:

Cables with low capacitance and high electrical insulation resistance

Cables with copper conductors (class 5) with improved flexibility.

Cables with a grounding system designed for the lowest possible impedance of the ground path. A system of three phase conductors (3C) plus three ground conductors (3G) arranged alternately and symmetrically ensures that potentially damaging common mode current (CMC) is contained and returned to the drive without adverse effects, particularly important in higher current applications.

Cables with a low impedance screen for reduced current reflection and increased system reliability. Shielding with a double aluminium-polyester screen plus tinned copper mesh provides the best performance (100% shielding) and prevents corrosion, minimising electromagnetic interference (EMI). Conversely, a cable with an inadequate shield (or no shield) can act as an antenna and be a source of radiated emissions.

XLPE insulated cables to facilitate maximum electrical performance and avoid the effect of voltage spikes.

Cables with an oil resistant, UV resistant and halogen free (LSHF) outer sheath in case of fire.

Technical Characteristics of the TOPDRIVE® ROZ1-K VFD (EMC) Cable

If you are looking for a cable for powering motors with variable frequency drives with the highest performance, the TOPDRIVE® ROZ1-K VDF (EMC) cable has been specially designed for use in installations where it is necessary to limit the effects of Electromagnetic Interference (EMI), also known as Radio Frequency Interference (RFI).

Flexible copper conductor (Class 5).

XLPE insulation.

Three phase conductors (3C), plus three earth conductors (3G) arranged alternately and symmetrically.

100% shielding. Double aluminium-polyester screen plus tinned copper mesh.

Chemical & oil resistance outer sheath.

Halogen-free outer sheath (LSHF) with CPR Cca classification.

Installations where TOPDRIVE® ROZ1-K VFD (EMC) 0,6/1 kV Cable is Suggested for Use

TOPDRIVE® ROZ1-K VFD (EMC) 0.6/1kV cable is the right cable for fixed installations, motors or variable speed pumps in:

Robots.

Conveyors.

Machines with repetitive or continuous motion.

Power generation plants.

Metallurgical industry.

Petrochemical industry and Gas (Oil & Gas).

Mines.

Water treatment.

Large Air Conditioning systems.

Cement plants.

General industry.