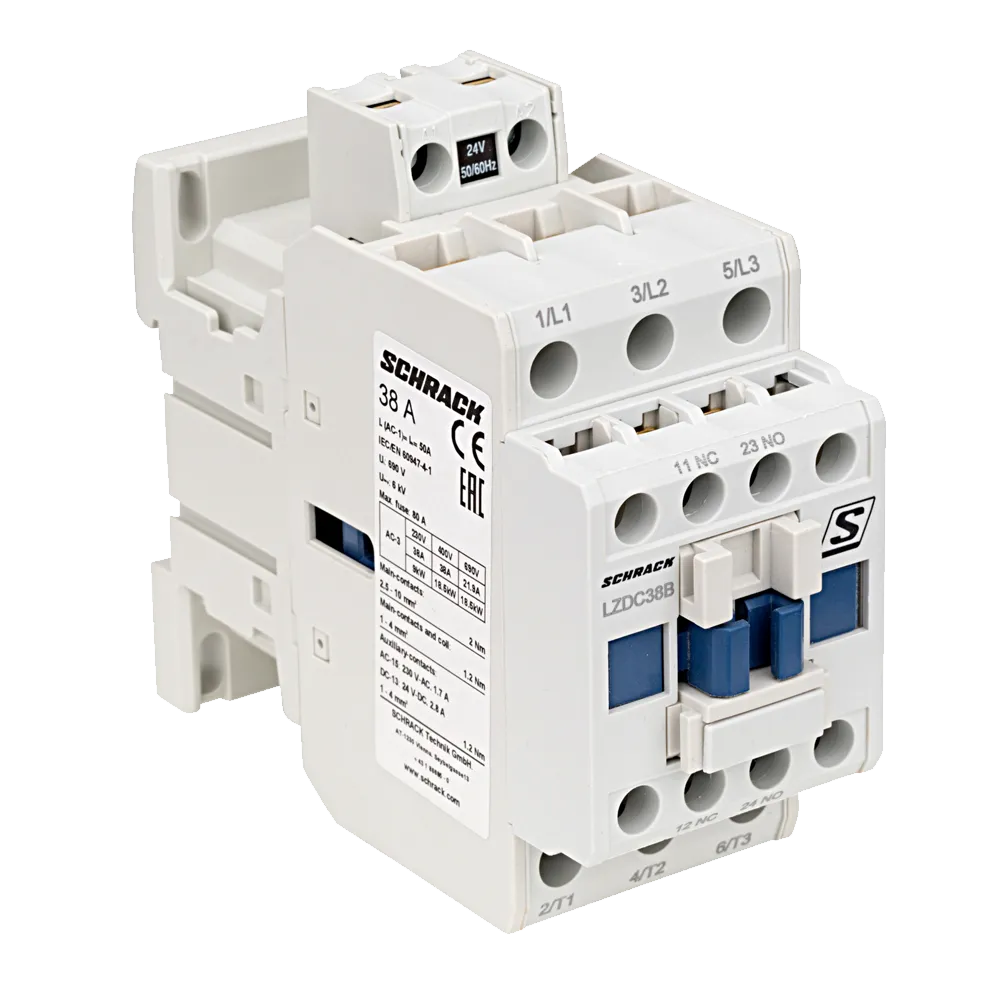

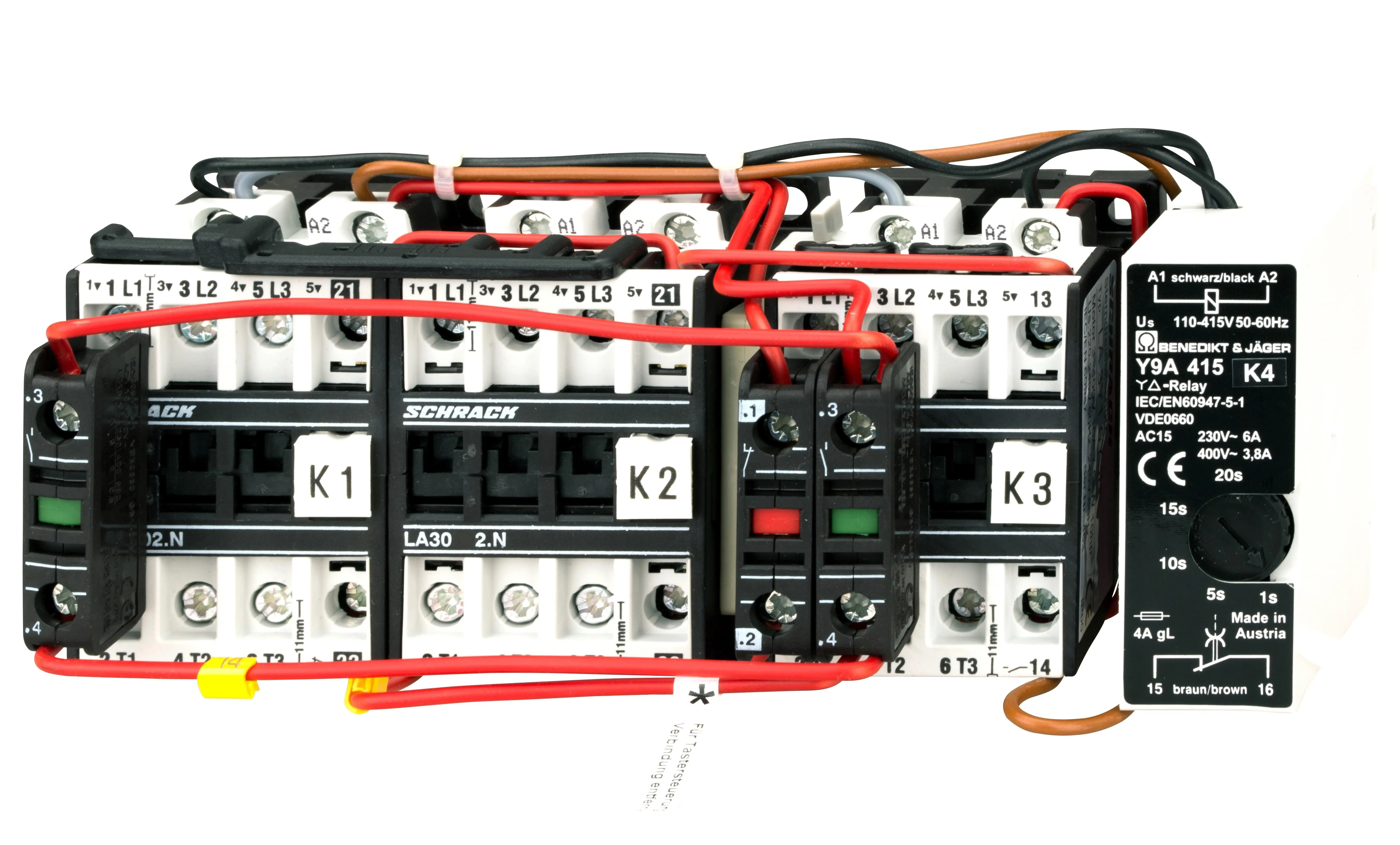

What is the Difference Between an AC Contactor and a DC Contactor?

The differences between AC contactors and DC contactors primarily stem from their design and performance characteristics tailored to their respective power sources. Here's a breakdown of the key distinctions:

1. Coil Design:

AC contactors typically use an iron core and coil with a laminated iron core to handle alternating current. The core design helps minimize energy loss and heat generation.

DC contactors use a straight iron core and coil without laminations since DC does not require the same efficiency considerations. DC coils are generally more straightforward in design.

2. Arc Suppression:

AC contactors are designed to handle the arc generated during switching due to the nature of AC current, which periodically crosses zero. Arc suppression methods are critical in AC contactors to prolong contact life and ensure safety.

DC contactors must manage the potentially continuous arc formed during switching since DC current does not naturally extinguish arcs like AC does. Special arc suppression techniques are employed to mitigate this issue.

3. Contact Materials

AC contactors often use materials that can handle frequent arcing, such as silver or silver-alloy contacts. These materials are suitable for handling AC currents effectively.

DC contactors require materials capable of withstanding the higher wear and tear caused by continuous arcing. Materials like tungsten are commonly used for DC contactors to ensure longevity and reliability.

4. Operation and Performance:

AC contactors are designed to handle the periodic changes in current direction and voltage levels associated with AC power. They are optimized for efficient operation under AC conditions.

DC contactors are specifically engineered to manage the steady flow of direct current without the alternating characteristics of AC. They are configured to break DC circuits reliably and safely.

5. Coil Ratings:

AC contactors have specific coil ratings optimized for AC voltage and frequency. Common AC coil voltages include 24V, 120V, or 240V AC.

DC contactors are rated for specific DC coil voltages, such as 12V, 24V, or higher, depending on the application requirements.

6. Application Suitability:

AC contactors are suitable for applications involving AC motors, lighting systems, and other AC-powered devices.

DC contactors are essential for DC motor control, battery systems, solar applications, and other DC-powered equipment.

In summary, AC and DC contactors are tailored to the unique characteristics and requirements of their respective power sources. Understanding these differences is crucial for selecting the right contactor for specific applications and ensuring reliable and safe operation within electrical systems.