Connectors for industrial and warehouse lighting

Lighting that improves your company's productivity

Inside industries and warehouses, lighting affects the well-being of workers, workplace safety and department productivity. The absence of natural light in production and logistics plants, however, forces companies to equip themselves with lighting systems that improve visual comfort and, in the meantime, reduce costs and CO2 emissions.

In the industrial sector, energy expenditure for lighting production departments is around 40%, a value that even reaches 80% in warehouses and logistics departments. For large companies, the use of LEDs as a light source becomes an almost obligatory choice to reduce costs and environmental impact , but the lighting systems must be carefully designed to function continuously and perform well.

In addition to light fixtures and LEDs, manufacturing companies must pay attention to the lighting project as a whole , and use components and connectors that can comprehensively respond to the needs of individual departments.

Techno solutions for industrial lighting

Thanks to close collaboration with companies producing lighting systems, our engineers have developed connectors capable of fully responding to the needs of industrial lighting. In closed spaces, where natural light is minimal and work shifts are constant, a well-designed system built with quality products improves environmental comfort, reduces downtime and increases the productivity of operators , reducing their visual stress. Our connectors keep the system performing over time and protect the electrical network from water and humidity infiltrations, dust and mechanical stress. Furthermore, the practicality of installing and inspecting the individual elements further optimizes the time necessary to make and maintain the system operational, giving an effective and targeted response for the lighting of warehouses, production departments, mining plants, Cash & Carry...

Connectors to illuminate every situation

Stores

Inside warehouses, the right lighting system helps operators move between the shelves and find items more quickly, reading codes and descriptions more precisely and without visual stress. Furthermore, it makes the environment more comfortable even when there is almost no external light.

Production departments

With the right lighting system, not only do you improve the well-being of workers, but you also prevent accidents at work and you can more accurately control the quality of the products produced, increasing productivity and the added value of your business.

Cash & Carry

In Cash & Carry warehouses, good lighting welcomes customers into a comfortable space, helps them move between the shelves and improves the shopping experience, increasing the return on investment both in terms of savings on electricity bills and in terms of new entries.

Mines

The mining sector is a challenge for the lighting sector, because every connection and every light body is exposed to dust, humidity, mechanical vibrations and the risk of explosions. Good lighting allows you to work continuously without putting the safety of workers at risk.

The advantages of good industrial lighting

A well-lit work environment prevents falls or accidents and helps workers to view writing, codes and details more precisely, avoiding trivial errors due to poor visibility in the warehouse or warehouse.

Furthermore, the use of latest generation systems reduces energy costs, limits Co2 emissions and reduces maintenance interventions. In production or logistics environments organized on work shifts and active 24 hours a day, high-performance lighting systems therefore equate to constant productivity and prevent departments from stopping simply due to lack of light.

Furthermore, in closed spaces, lighting systems directly influence people's well-being because they make the environment more welcoming, reduce visual stress and promote concentration.

To obtain all these advantages, manufacturers of lighting solutions are called upon to study systems that perform in every aspect , from materials to the use of LEDs, from the design of the system to the choice of connectors that meet the specific needs of the industrial and logistics sector.

The technical needs of industrial lighting

Duration

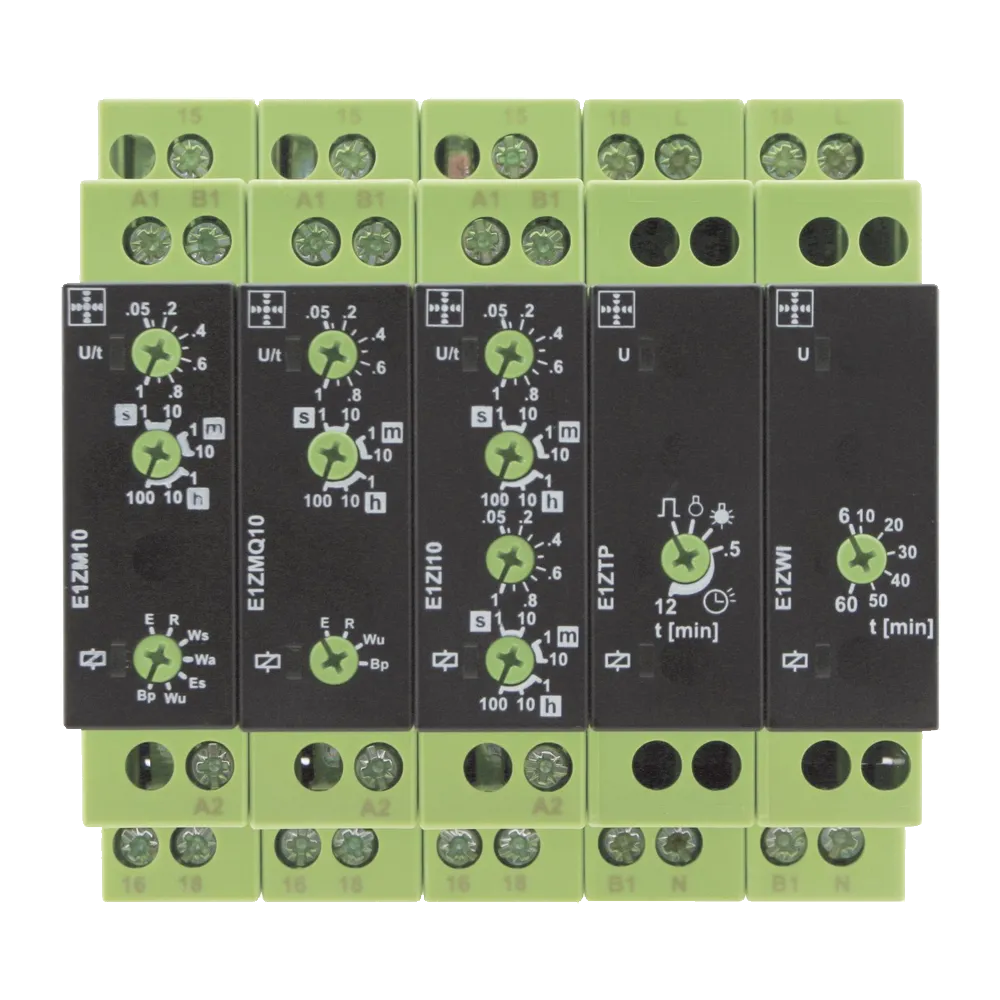

Within the production and logistics departments, we often work in shifts and the department remains operational 24 hours a day. The lighting system must be carefully designed and the individual connections must be able to last over time without the need for continuous maintenance.

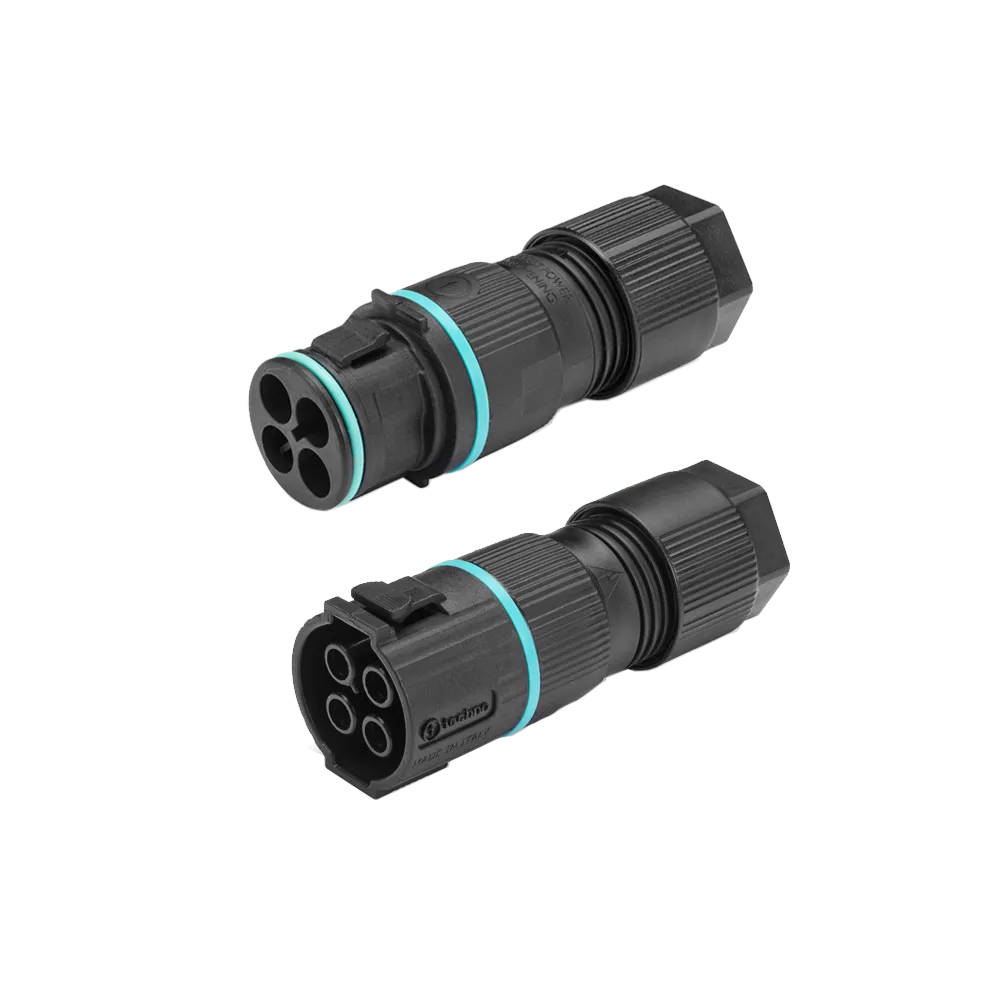

Moisture resistance

In closed environments, the formation of condensation and humidity is common, especially in the warmer months and in the presence of production plants that generate heat. Electrical connections must be designed to avoid contact between external moisture and internal cables.

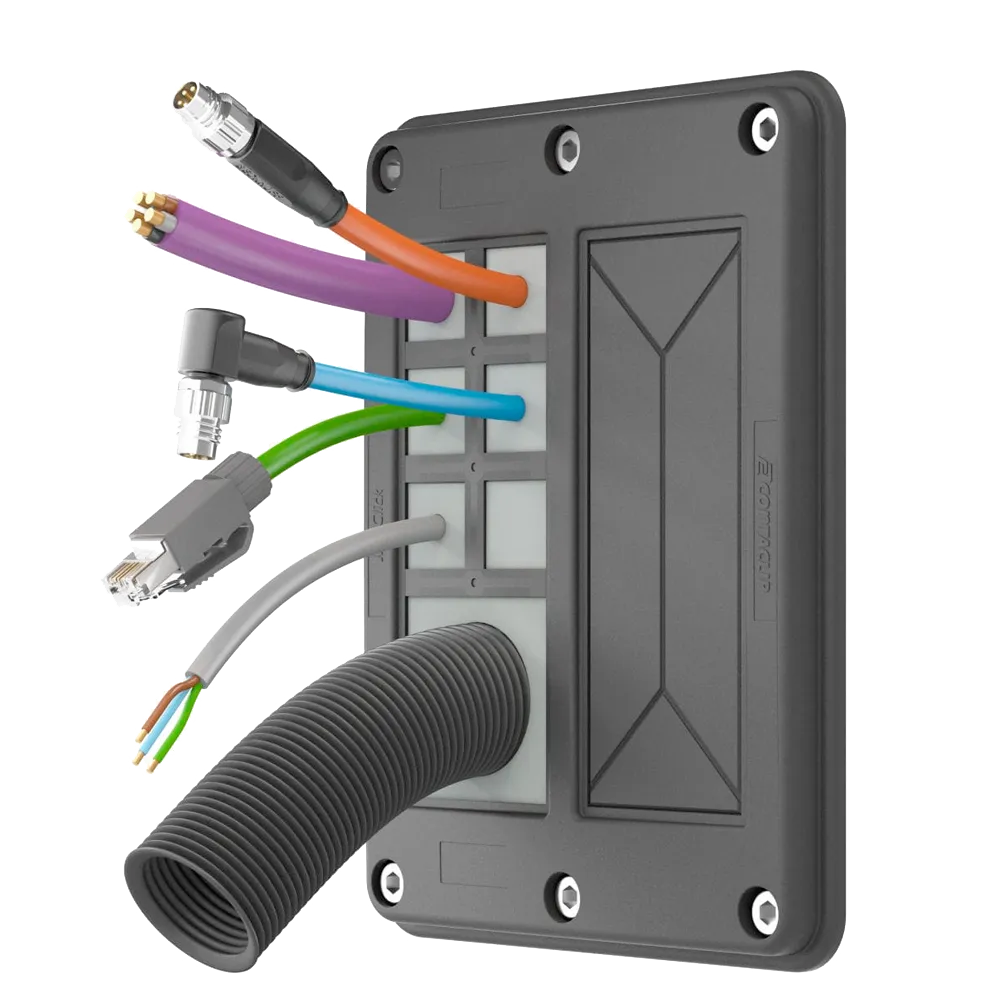

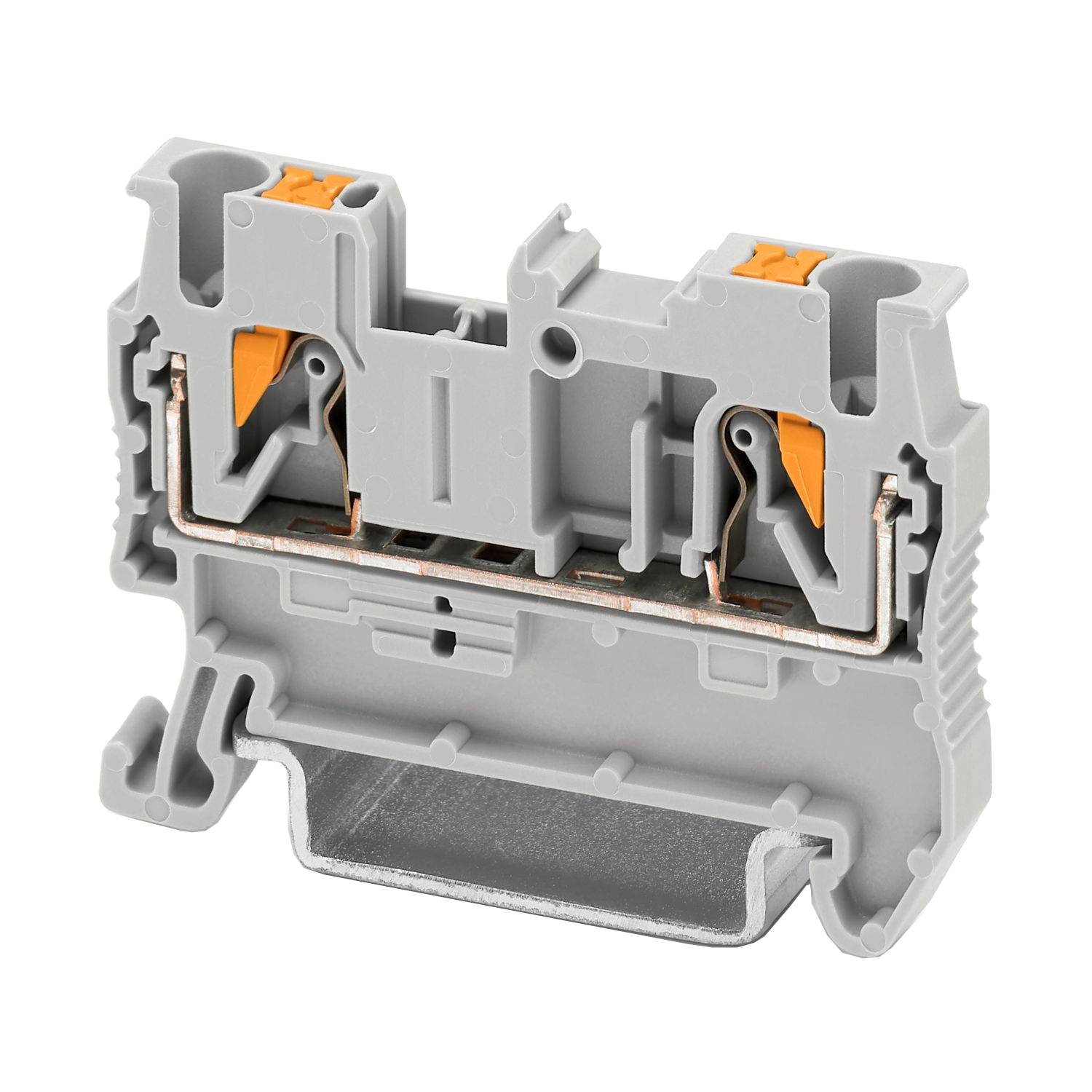

Series connections

Within the production departments, the design of a modular lighting system allows you to optimize times and costs both during the construction and maintenance phases. Furthermore, thanks to efficient connections, it is also possible to optimize the on/off times of the entire system.

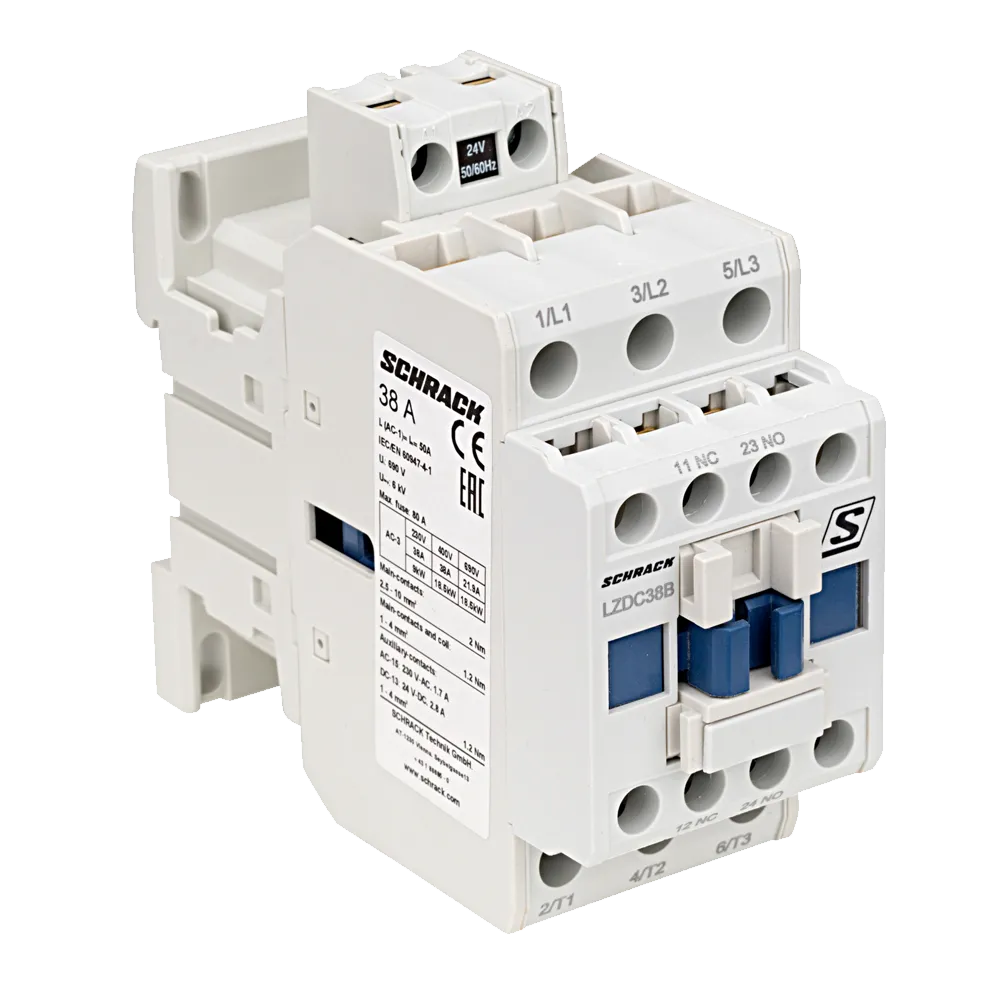

Fire resistant

Inside production plants and warehouses, there can never be too much attention to safety in the event of fire. In lighting systems there is a need to have safe connections, with cable-cable or socket-plug solutions made of self-extinguishing material.

Dust resistance

In production environments, dust is the order of the day. The connections and lamp bodies must be made so that dust does not come into direct contact with the cables, thus preventing short circuits and malfunctions of the lighting system.

Constant diffusion

Voltage changes can cause sudden flickering which, in the long run, strains the eyes, causing accidents and errors at work. The use of quality connections, however, ensures a continuous supply of energy which allows the lamp bodies to spread the light evenly and make the environment more welcoming.

Reduced heat

Heat affects the well-being of employees, their concentration and the productivity of departments. In production departments, where the machinery already produces a high amount of heat, choosing LED systems and efficient connections that prevent heat dispersion reduces the temperature of the environment, making it more comfortable.

Easy connection

Even in the industrial and logistics sector, needs change and the entire lighting system must be able to adapt to production requests. It is therefore necessary to design and build it with solutions that are easy to install, with plug & play connections and structures with intuitive wiring that prevent accidents, tampering and errors during the installation phase.

Small size

The possibility of designing lighting systems with small cables and connectors improves the overall appearance of the system, makes it tidier and avoids the invasive presence of electrical elements within the departments and warehouses.

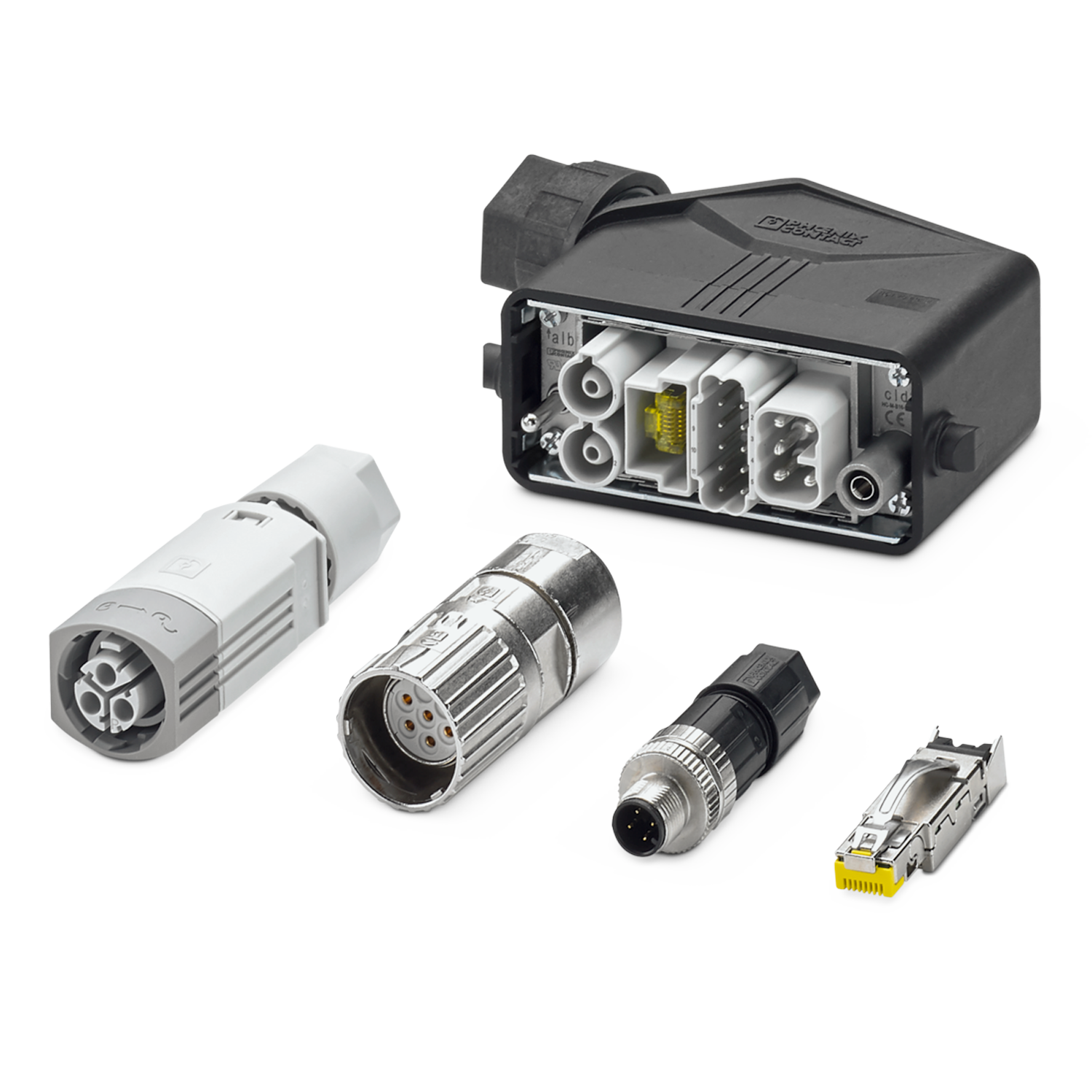

Techno connectors for the lighting of industries and warehouses

For the industrial and logistics sector we have designed connectors that can be easily installed, last over time, and resist the harsh conditions present in production departments and warehouses. The socket-plug and cable-cable connections of the TEEPLUG® line are an example of this. These are UL/CSA certified connectors in accordance with the Type 6/6P level, which resist extreme conditions, such as immersion in water. Furthermore, they are made with self-extinguishing raw materials that are resistant to wear, creep and high temperatures.

Connectors tailored to your idea of light

In addition to the production of standard connectors born from the needs of the lighting sector, the technical preparation of our engineers pushes us to face new challenges every day and design connectors tailored to specific application needs.

Don't put limits on your creativity! Design the lighting spaces you want: we'll take care of the reliable connections!

Check out our connectors for industrial and warehouse lighting: