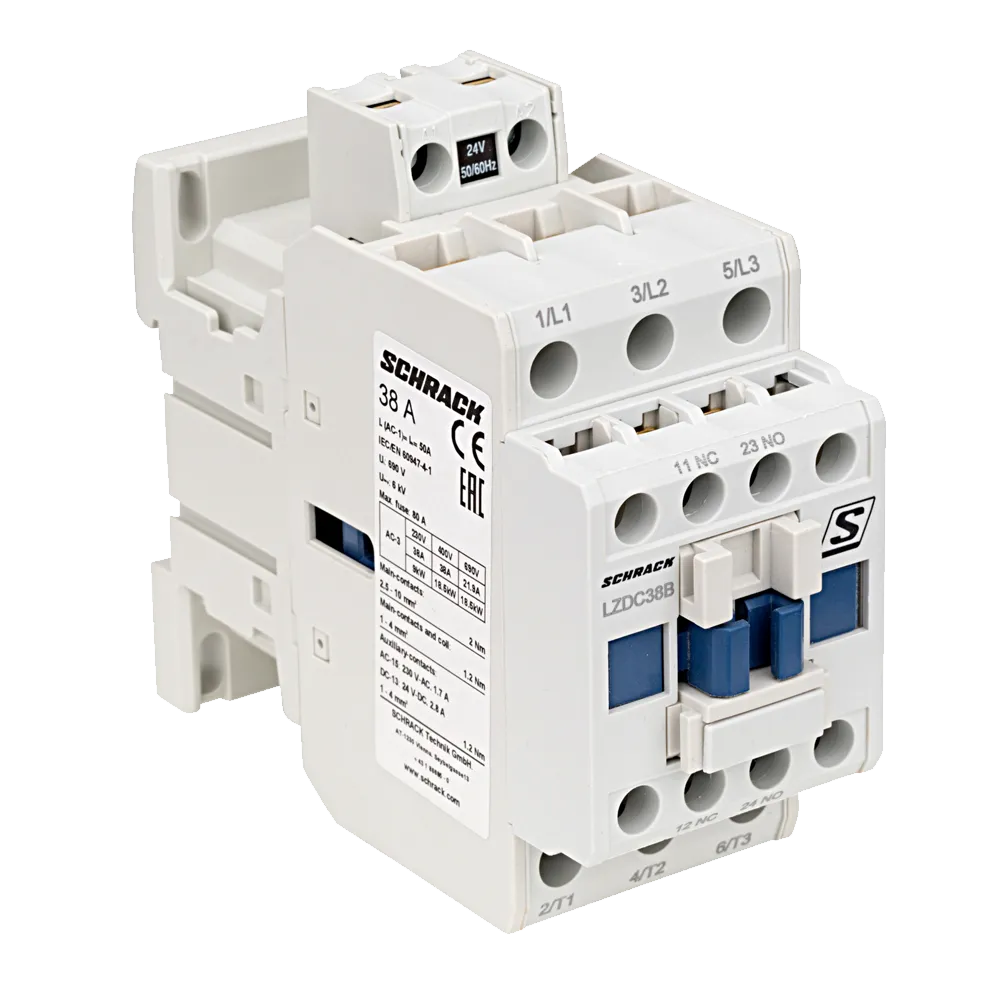

Engineering Considerations for Selecting Mains Switches, Isolators & Disconnectors - and Why Schrack Is a Trusted Choice

Isolation devices might be simple in principle, but choosing the right one has a real impact on safety, serviceability and equipment behaviour. In industrial panels, mechanical services and OEM-built equipment, the details such as switching duty, contact behaviour, compliance and installation environment drive whether an isolator performs reliably over time.

This guide focuses on the engineering considerations that influence device selection and why many professionals rely on Schrack for consistent, predictable isolation in demanding environments.

1. What Really Drives Isolation Selection in Industrial Applications

In industrial panels and machinery, selection usually hinges on switching duty, mechanical behaviour and compliance. These factors determine how the switch performs in practice.

Electrical professionals look beyond ratings to understand:

• how often the device will be operated

• the nature of the connected load

• the expected inrush or mechanical switching duty

• the environmental and mechanical stresses

• the serviceability requirements of the equipment

These considerations ensure the device selected is appropriate for the installation and its long-term maintenance needs.

2. Switching Categories: A Frequent Source of Selection Issues

Switching categories are a frequent source of selection issues, especially when isolating inductive or high-inrush loads.

When AC23A is essential

Loads with high inrush or inductive characteristics:

• HVAC compressors and fans

• Pump motors

• Machinery with frequent start and stop cycles

• Mixed mechanical services equipment

AC23A devices are designed to break current under these more demanding conditions. In these installations, using a device rated only AC21A or AC22A can lead to premature wear, inconsistent break performance or service challenges.

This is a key reason many OEMs and HVAC contractors select Schrack’s LT(S) range because the AC23A capacity is both reliable and repeatable.

Where AC21A and AC22A still make sense

• Resistive loads

• Simple isolation points

• Distribution boards with predictable duty

The right choice reduces cost while maintaining performance.

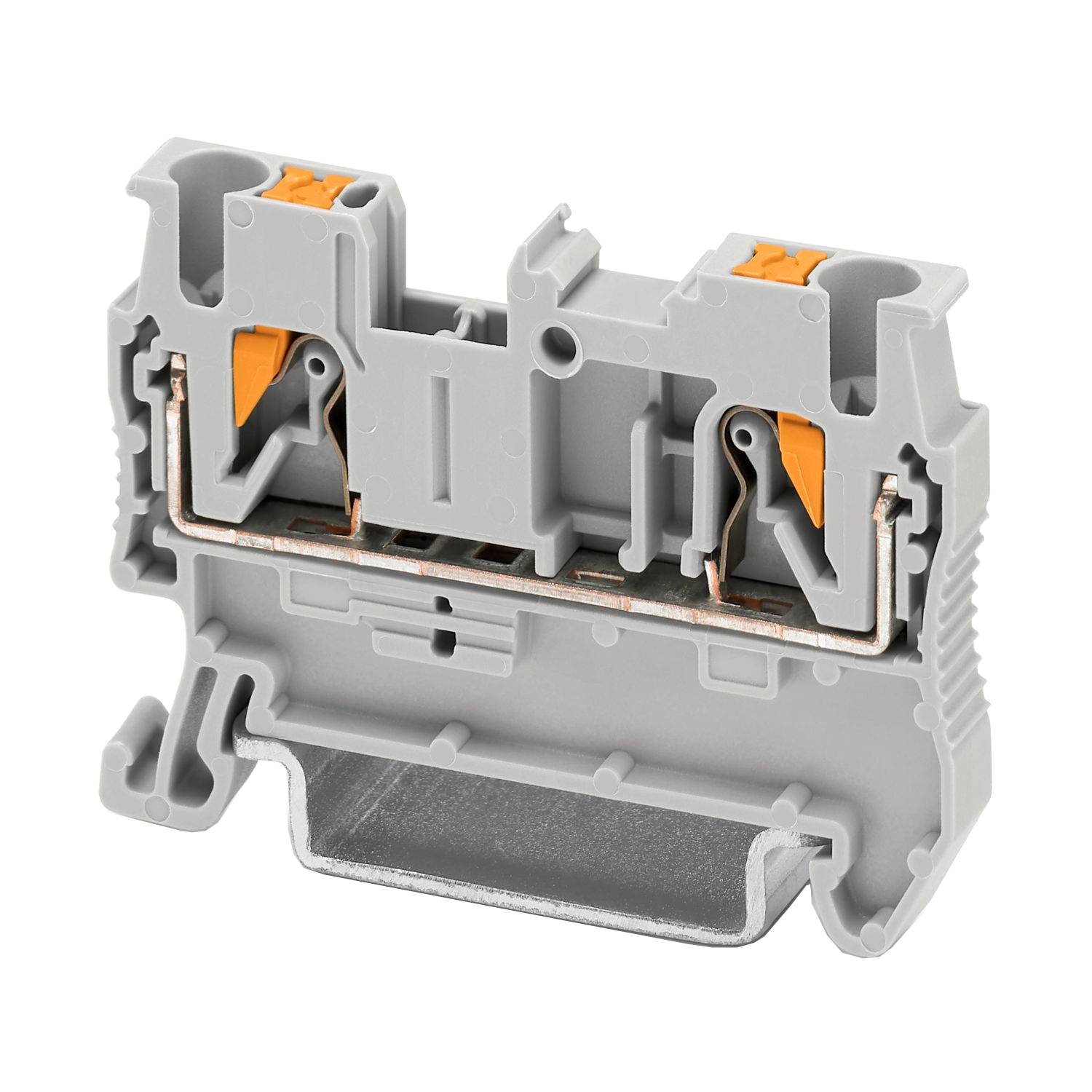

3. Contact Gap Size: A Practical Safety Advantage

Large contact gaps matter, especially in machinery and equipment that relies heavily on safe lockout and tagout procedures.

Schrack isolators use large contact gaps, providing:

• clear, visible disconnection

• greater confidence during maintenance

• reduced risk of partial or uncertain isolation

• improved safety when multiple teams share servicing responsibilities

This is particularly important on sites where mechanical; HVAC and electrical personnel collaborate during maintenance.

4. How Standards Influence Performance (Not Just Compliance)

IEC EN 60947-3 and IEC EN 60204 define how isolators must behave beyond the nameplate ratings.

These standards govern:

• breaking capacity under different duties

• dielectric strength

• isolation distances

• mechanical life

• endurance characteristics

Professionals choose Schrack because it meets these requirements with consistent manufacturing quality, reducing the likelihood of unexpected behaviour during operation or servicing.

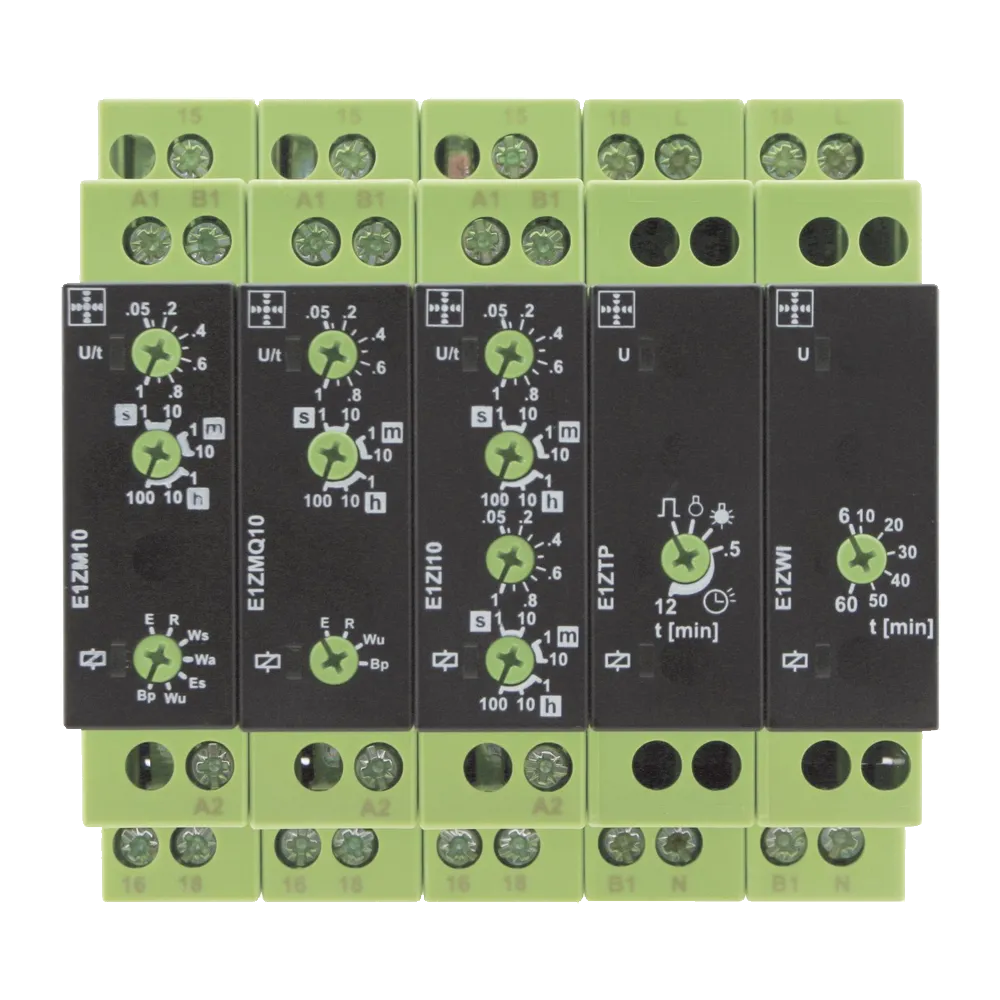

5. Practical Considerations for OEMs, Switchboard Builders and HVAC Contractors

Frequent operation

Machinery and HVAC systems often require regular isolation for service. Mechanical life becomes critical.

Neutral isolation

4-pole isolators are required when neutral integrity cannot be guaranteed or when mandated by equipment design.

690 V ratings

Industrial and mechanical installations often require switches capable of 690 V even when operating on lower system voltages.

Environmental exposure

Dust, moisture, vibration and temperature all influence device longevity. Enclosed isolators or higher IP options may be necessary.

Accessible lockout points

Clear ON OFF indication and reliable mechanical feedback are essential for safe LOTO procedures, especially in multi-discipline sites.

These considerations directly influence equipment reliability and service efficiency.

6. Common Selection Pitfalls and How to Avoid Them

Choosing AC22A when AC23A is needed

A frequent cause of premature wear in inductive load applications.

Underestimating mechanical operation cycles

HVAC and machinery maintenance schedules can be intensive and device endurance matters.

Not isolating neutral when required

This can impact equipment behaviour or system performance.

Using open isolators in dusty or wet areas

Ingress shortens lifespan and enclosed options prevent early degradation.

Assuming all isolators perform similarly under load

Switching behaviour varies significantly between models and brands.

Avoiding these issues reduces rework, improves safety and supports more predictable equipment performance.

7. Why Schrack Is a Preferred Choice for Industrial Isolation

Professionals often choose Schrack mains switches, isolators and disconnectors because they provide:

• Reliable AC23A switching capacity for demanding inductive loads

• Large contact gaps for confident, verifiable isolation

• Consistent load break performance

• Clear ON OFF indication supporting safer LOTO practices

• Compliance with IEC EN 60204 and IEC EN 60947-3

• Reliable mechanical operation for isolation tasks

In short, Schrack offers dependable isolation performance where it matters most on equipment that is serviced regularly and expected to operate safely for years.

8. The Schrack Range at Switches Plus

Switches Plus supplies a wide range of Schrack mains switches, isolators and disconnectors for industrial and commercial installations. With options across switching duties, pole configurations and current ratings, selecting a compliant and reliable device is straightforward.

Our team can assist with matching the right switch to your load type, environment and standards requirements.

Conclusion

Isolation devices may be simple components, but choosing the right one has a measurable impact on equipment safety, serviceability and performance. By focusing on switching duty, contact gaps, environmental conditions and standards, professionals can ensure reliable isolation across machinery, HVAC systems and industrial plant.

Schrack’s proven performance and consistent behaviour under load make it a trusted choice for demanding industrial environments.

If you need help selecting the right Schrack mains switch, isolator or disconnector, our team is here to assist.