When IO-Link makes sense and how to apply it effectively

IO-Link has become a well-established part of modern machine and system design. As the first globally standardised I/O communication technology, it is now widely supported across sensors, actuators, and an expanding range of field devices.

As adoption has grown, so too has the range of ways IO-Link can be applied. The design question is no longer what IO-Link is, but how to apply it effectively within a system.

The examples and capabilities discussed in this article are informed by Phoenix Contact’s IO-Link portfolio and application guidance.

Well-designed systems apply IO-Link where its capabilities support the application, while continuing to use conventional I/O where simplicity is the better fit.

IO-Link as a system capability

Within Phoenix Contact’s IO-Link range, devices are designed to support bidirectional communication between the field level and the control system. Alongside process values used for control, devices can also provide diagnostic information, identification data, and configurable parameters that can be stored and restored centrally.

Together, these capabilities support improved visibility, faster troubleshooting, and consistent device replacement. Their impact is strongest when they are applied deliberately as part of an overall system design, rather than uniformly across every signal point.

Where IO-Link is most effective

In Phoenix Contact’s IO-Link implementations, the technology is particularly well suited to applications where device level information and configuration support efficient operation over the life of the system.

This commonly includes:

Devices that benefit from parameterisation or adjustment during commissioning or operation

Signal points that are difficult to access, where diagnostics reduce intervention time

Applications where condition information supports planned maintenance

Equipment where consistent device replacement helps reduce commissioning effort and human error

In these environments, centralised parameter storage and diagnostic data can help minimise downtime and simplify maintenance tasks. The value comes from using the available information to support operational decisions, rather than from the communication itself.

Applying IO-Link intentionally

In simpler, static signal points, the additional capabilities offered by IO-Link may not be required to achieve reliable operation. In these cases, conventional I/O can remain a practical and effective choice.

This does not limit the role of IO-Link. Instead, it highlights the importance of matching capability to application needs. Systems that combine IO-Link devices and conventional I/O thoughtfully often achieve a strong balance between functionality, simplicity, and long term maintainability.

Looking beyond sensors the broader IO-Link ecosystem

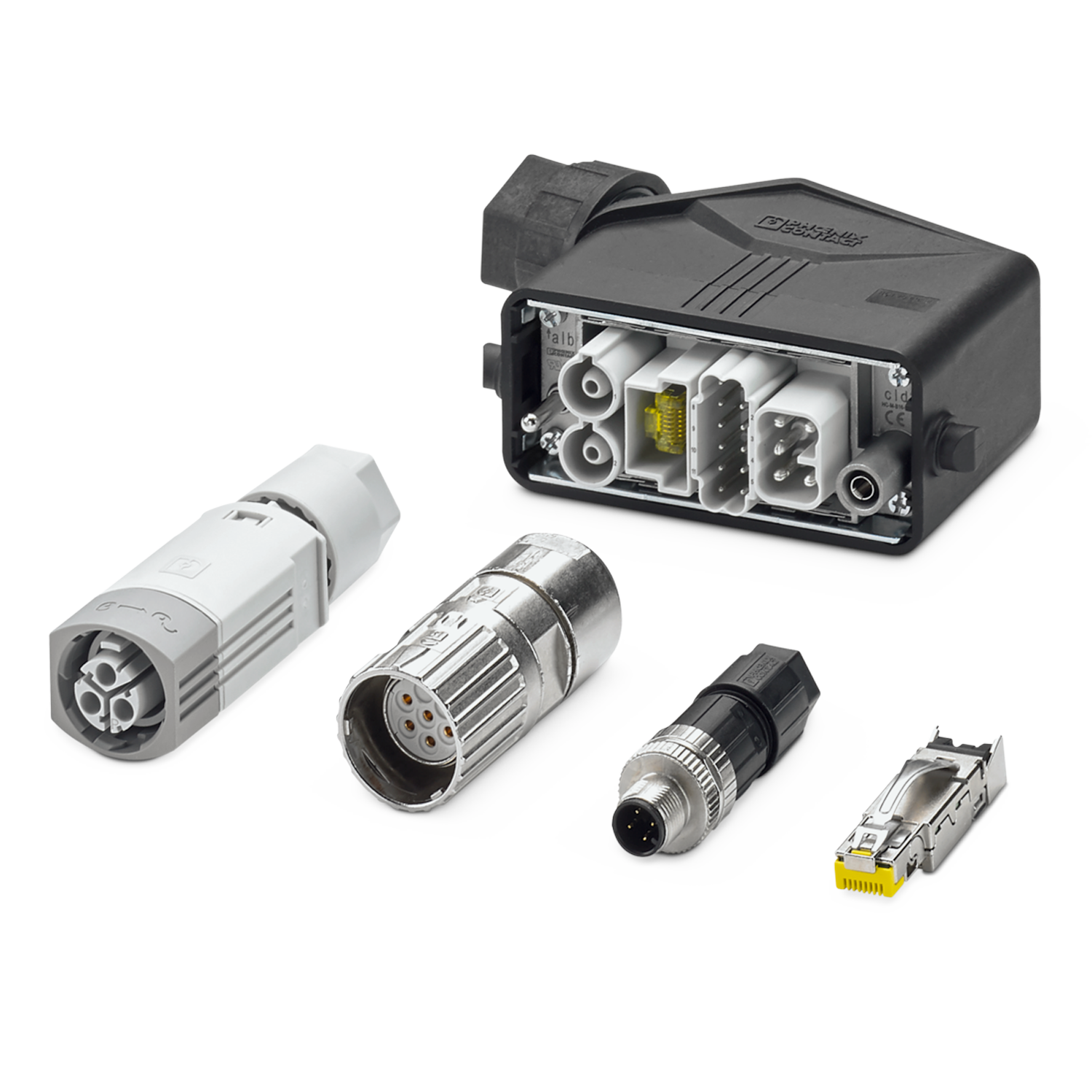

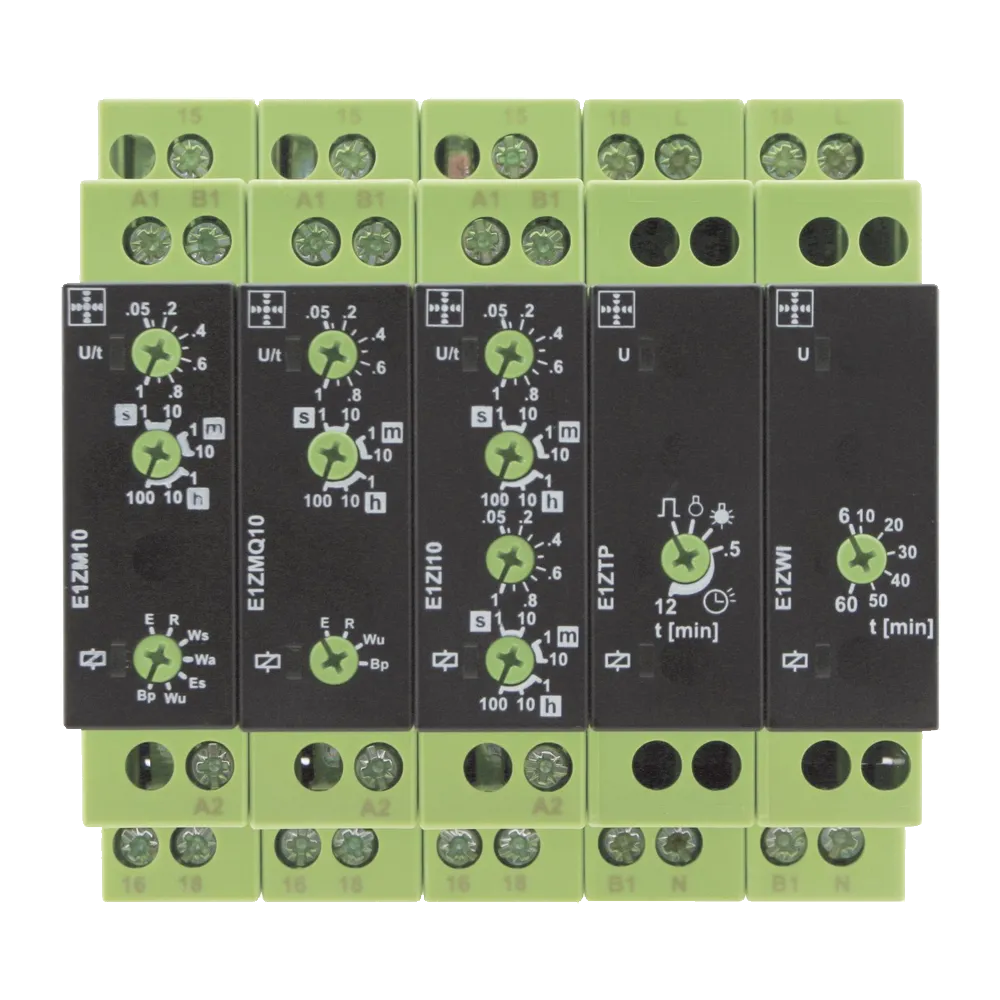

Within Phoenix Contact’s IO-Link portfolio, the technology extends well beyond sensors.

IO-Link enabled devices include:

Remote I/O systems

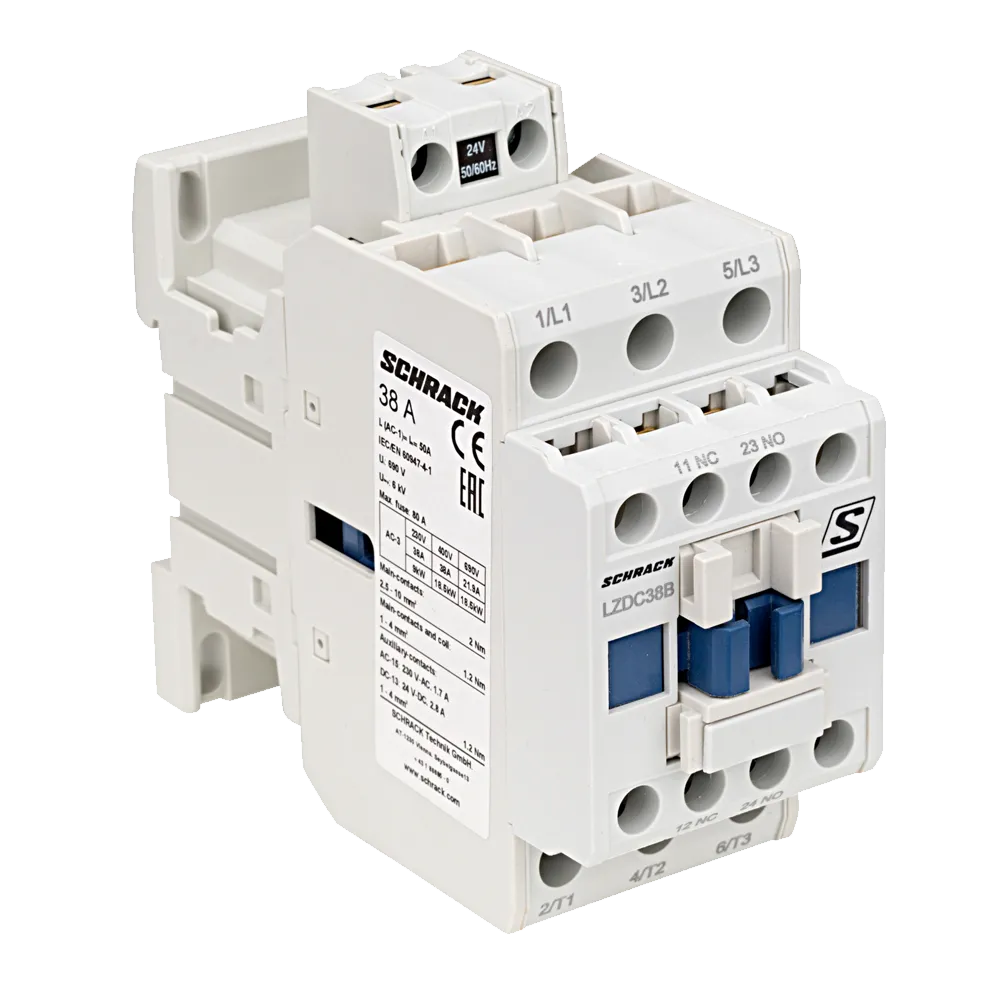

Circuit breakers with diagnostic feedback

Motor starters with configurable behaviour

Signal towers capable of reporting status and faults

Considering these devices together allows designers to apply IO-Link where device level intelligence improves system operation, without forcing uniformity across every signal point. This broader view supports scalable system architectures that can adapt as operational requirements evolve.

Contactless IO-Link couplers as a targeted solution

Within this broader ecosystem, contactless IO-Link couplers are designed for applications with specific mechanical or environmental constraints.

In Phoenix Contact’s range, these couplers are typically applied where:

Movement or separation is unavoidable

Physical connectors are exposed to wear or contamination

Frequent coupling and decoupling is required

Mechanical alignment benefits from additional tolerance

In these scenarios, contactless transmission can simplify mechanical design and reduce maintenance intervention. As with other IO-Link devices, their strength lies in addressing defined challenges, rather than replacing conventional connections universally.

Designing IO-Link systems with intent

Effective IO-Link systems are rarely uniform. In practice, they combine IO-Link devices and conventional I/O based on access, risk, and operational requirements.

The goal is not to maximise the number of IO-Link nodes, but to apply them where diagnostics, configurability, and data visibility support the application across its lifecycle.

When approached this way, IO-Link becomes a practical tool for building systems that are reliable, maintainable, and well matched to their operating environment.