Building Better Terminal Strips: How CLIPLINE complete helps you standardise, simplify and work faster

Terminal strips today are built using a wide mix of connection methods, accessories and conductor sizes, which can make standardisation difficult. Different projects call for different connection technologies, wiring methods and installation conditions. Add in varied accessories, multiple part numbers and pressure to deliver builds quickly and consistently, and it becomes clear why many teams look for ways to streamline their approach.

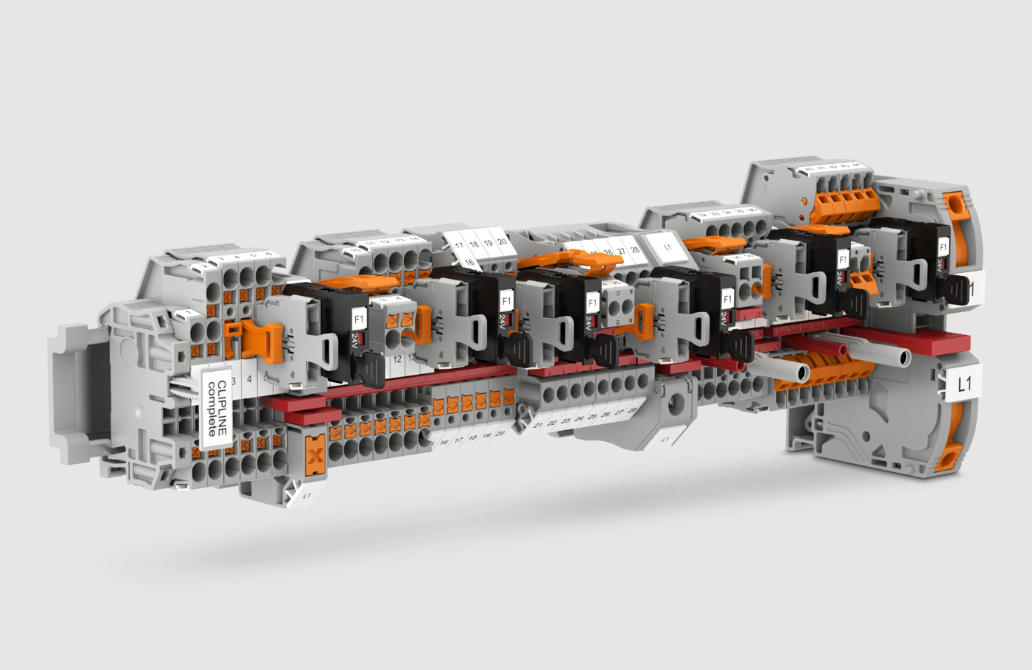

Phoenix Contact’s CLIPLINE complete system is designed around exactly that need, a single platform that supports multiple connection technologies, uses a shared accessory system and enables a consistent method for assembling terminal strips.

Below, we explore how the system works and the practical value it offers switchboard builders, panel builders, OEMs and industrial electricians.

The challenge: too many systems and too little standardisation

In many workshops, a typical terminal strip contains several connection technologies. Some applications require screw terminals, others need Push in or insulation displacement, while vibration sensitive areas might need spring cage. Usually, each technology comes with its own accessory set including bridges, markers, test plugs and cross section solutions.

This leads to familiar challenges:

more part numbers to manage

accessory incompatibility between terminal families

different assembly approaches depending on the technology used

variation between builds

slower workflows and higher risk of rework

The result is unnecessary complexity across the entire build process.

A unified platform for mixing technologies

CLIPLINE complete removes this fragmentation by providing a single terminal block platform where multiple connection technologies can be freely combined.

The system is built around a consistent design concept:

one double function shaft

one family of bridging solutions

standardised marking and test accessories

compatibility across all supported connection technologies

This gives switchboard builders, panel builders and OEMs the freedom to select the most appropriate connection method for each part of a terminal strip without switching between accessory families or rethinking their assembly process.

The double function shaft: consistent alignment across all blocks

The double function shaft is the structural foundation that makes system wide compatibility possible. Every CLIPLINE complete terminal block shares this same interface, allowing accessories and bridges to fit across the platform.

For installers, this provides:

a consistent bridging approach

universal test points

uniform marking options

predictable physical alignment

Because all blocks use the same accessory interface, teams can work with a consistent approach across the entire system, regardless of which connection technology is chosen.

Standardised accessories for faster, cleaner builds

Bridging is often one of the most time consuming and error prone aspects of terminal strip construction. CLIPLINE complete simplifies this with a single accessory range that works across all connection technologies.

This includes:

2 to 50 position bridges

reducing bridges for mixed cross sections

freely pluggable wire bridges for flexible configurations

Marking and test accessories are also standardised, reducing the number of individual parts needed across projects and keeping assembly methods consistent from one build to the next.

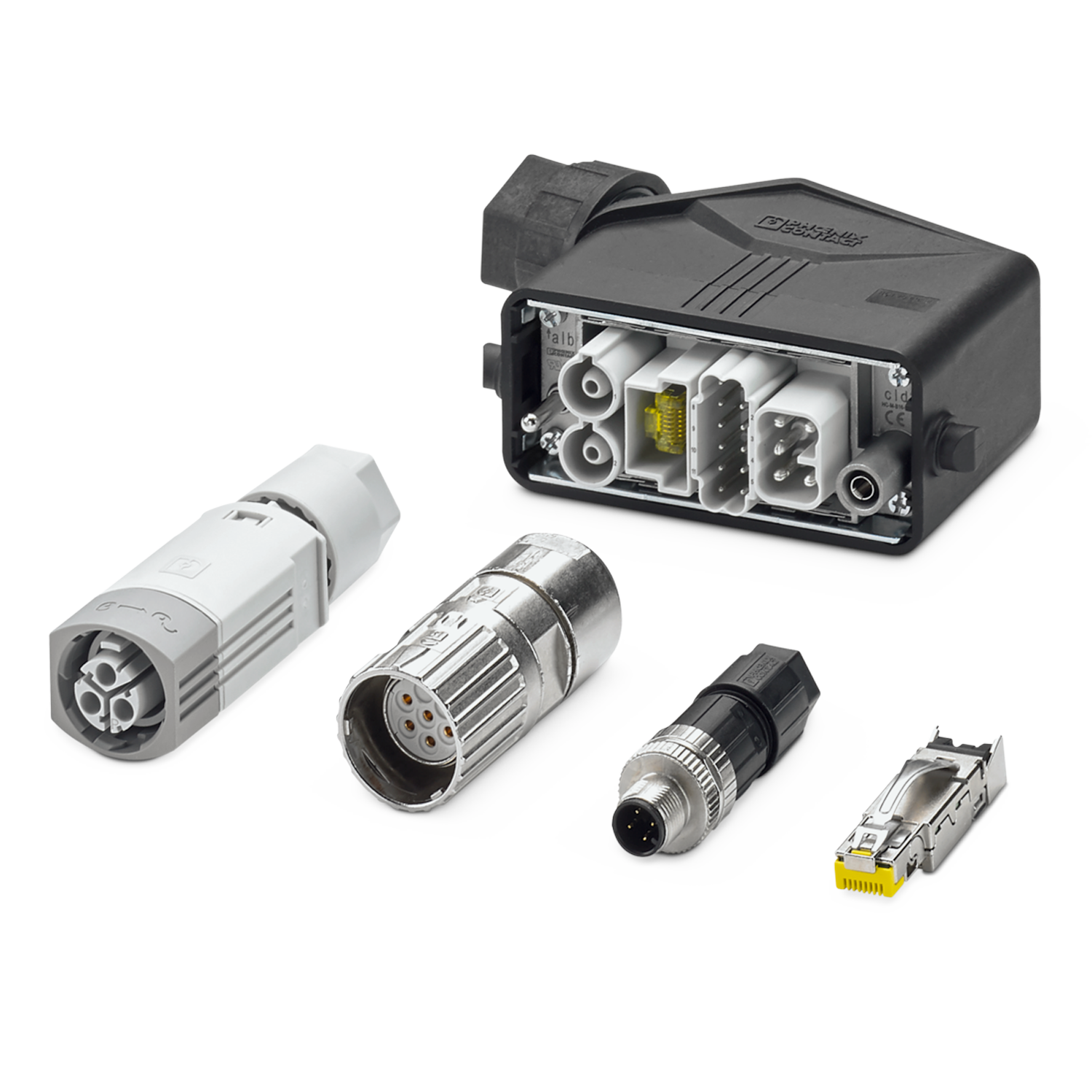

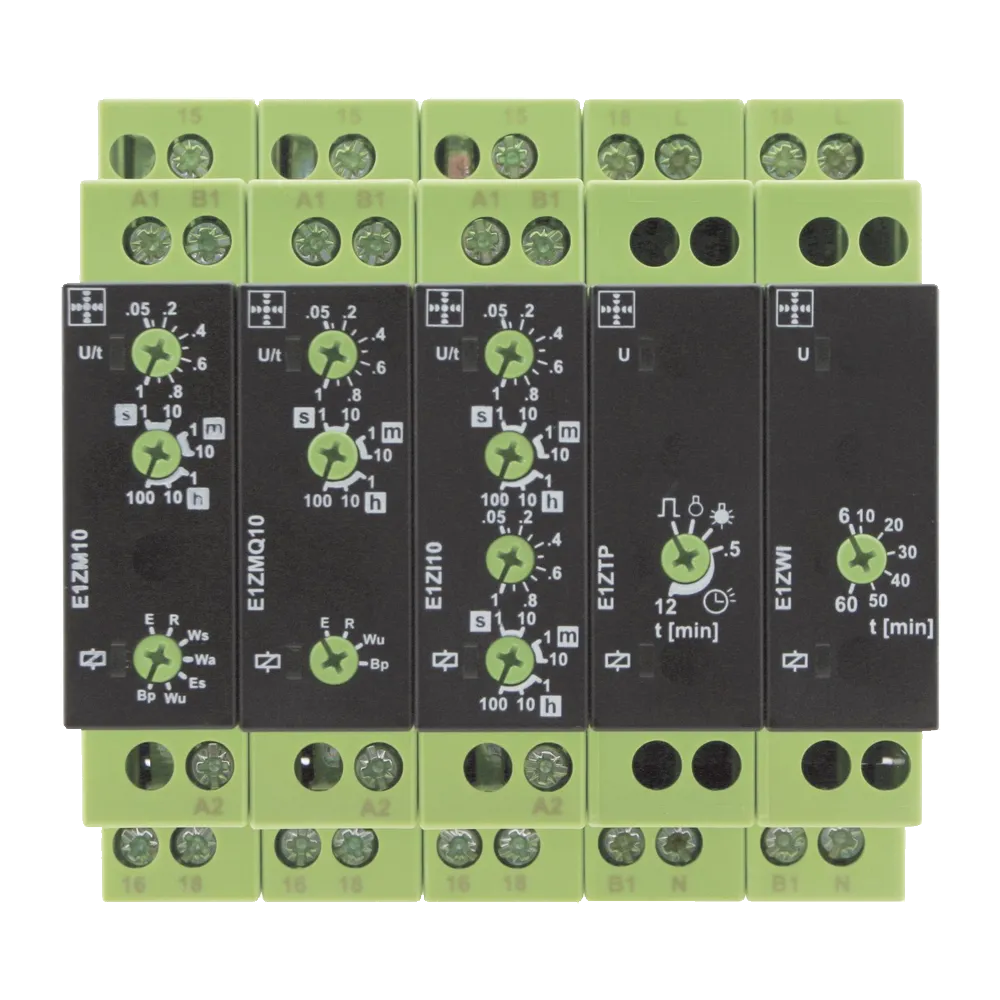

Seven connection technologies and where each one fits best

CLIPLINE complete supports seven connection technologies. Because they can all be combined within one platform, switchboard builders, panel builders and OEMs can optimise each part of the terminal strip to suit the application.

PT Push in Connection

Tool free insertion from 0.25 mm² with up to 50 percent lower insertion forces due to the special contact spring.

Best for fast, repeatable control wiring.

PTV Lateral Push in Connection

Provides lateral conductor entry with tool free Push in convenience. This combines the clear routing found in screw type terminals with the speed of Push in technology.

Best for neat, space efficient wiring where forward conductor entry is difficult.

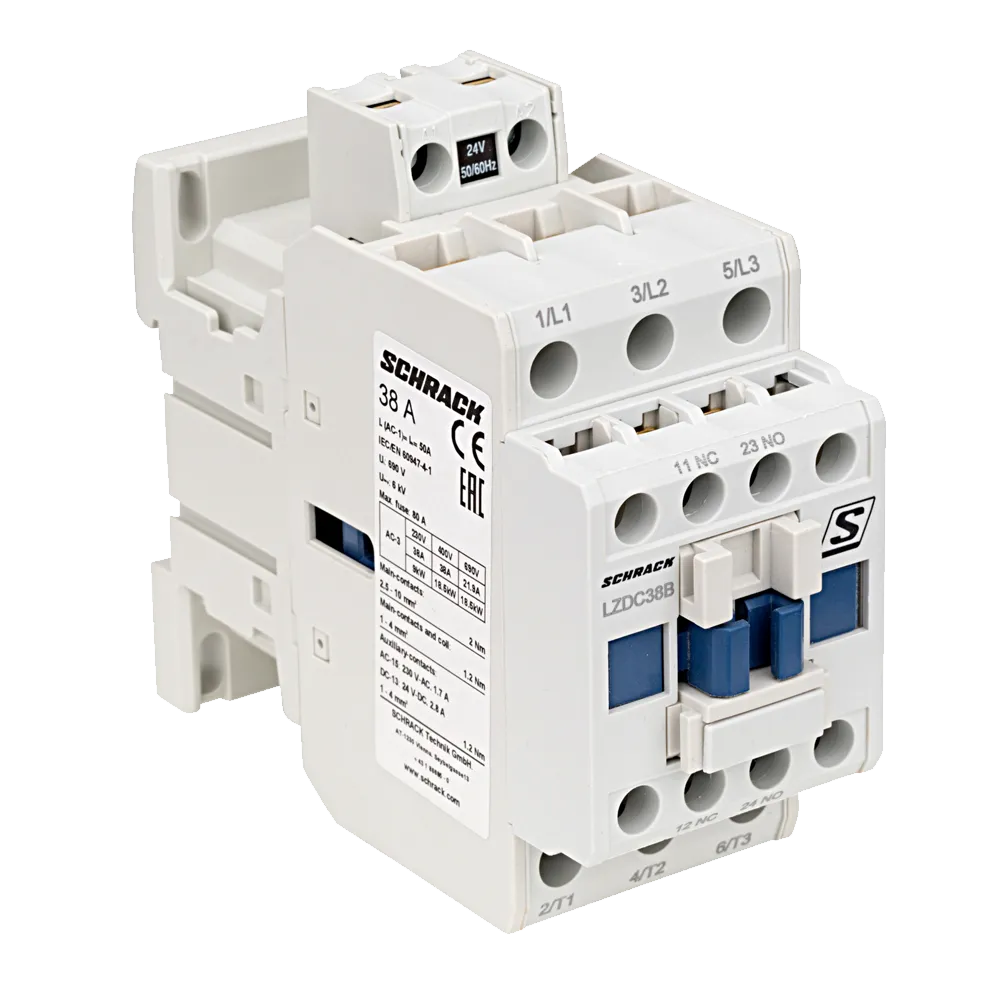

UT Screw Connection

High contact force, supports multiple conductors and is widely accepted globally.

Best for universal use and internationally consistent designs.

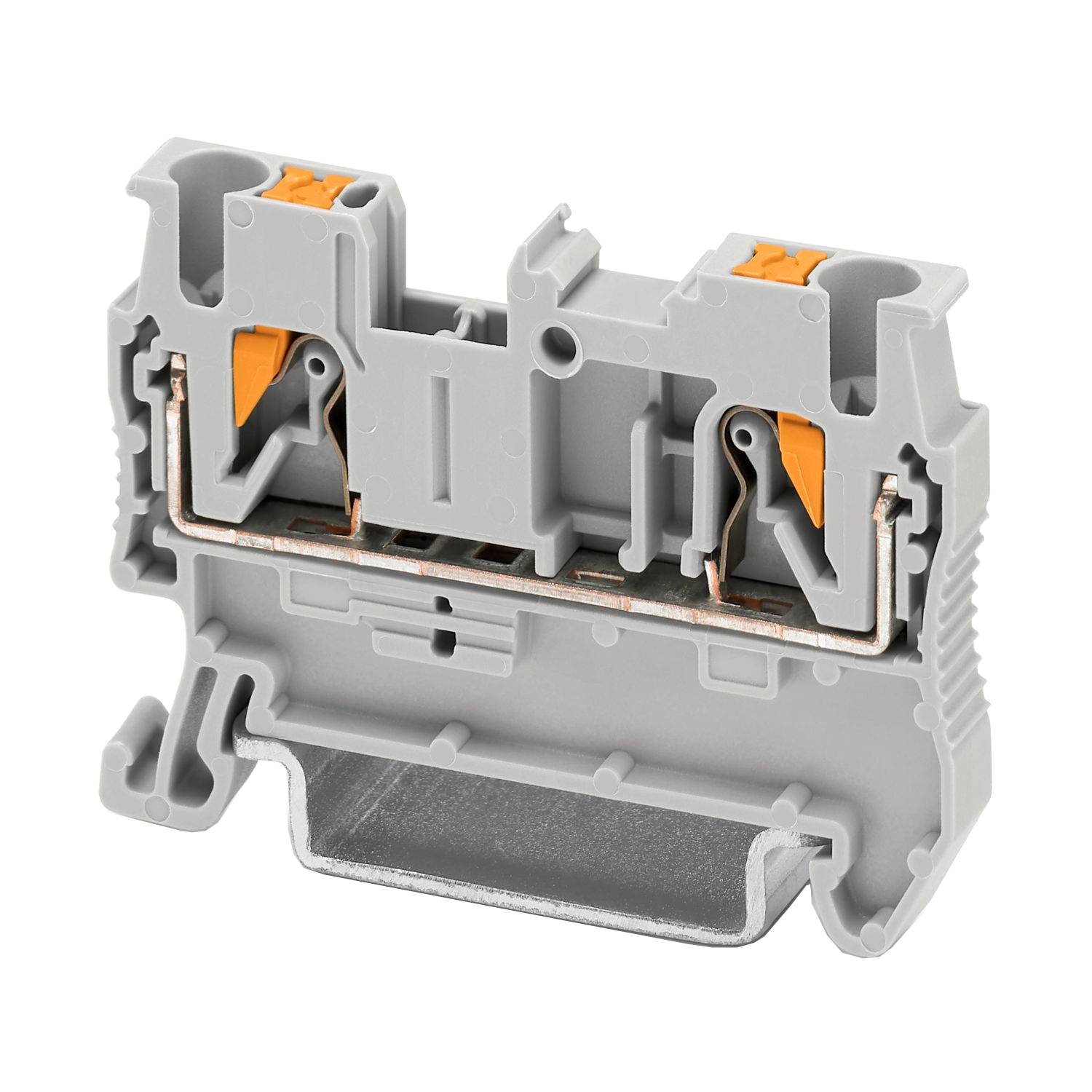

ST Spring Cage Connection

Provides consistent contact force, suitable for vibration sensitive environments.

Best for machinery, transport and installations subject to movement.

QT Fast Connection IDC

Connect conductors without stripping insulation. Wiring is completed in one screwdriver turn with up to 60 percent time savings.

Best for rapid installation or repetitive wiring tasks.

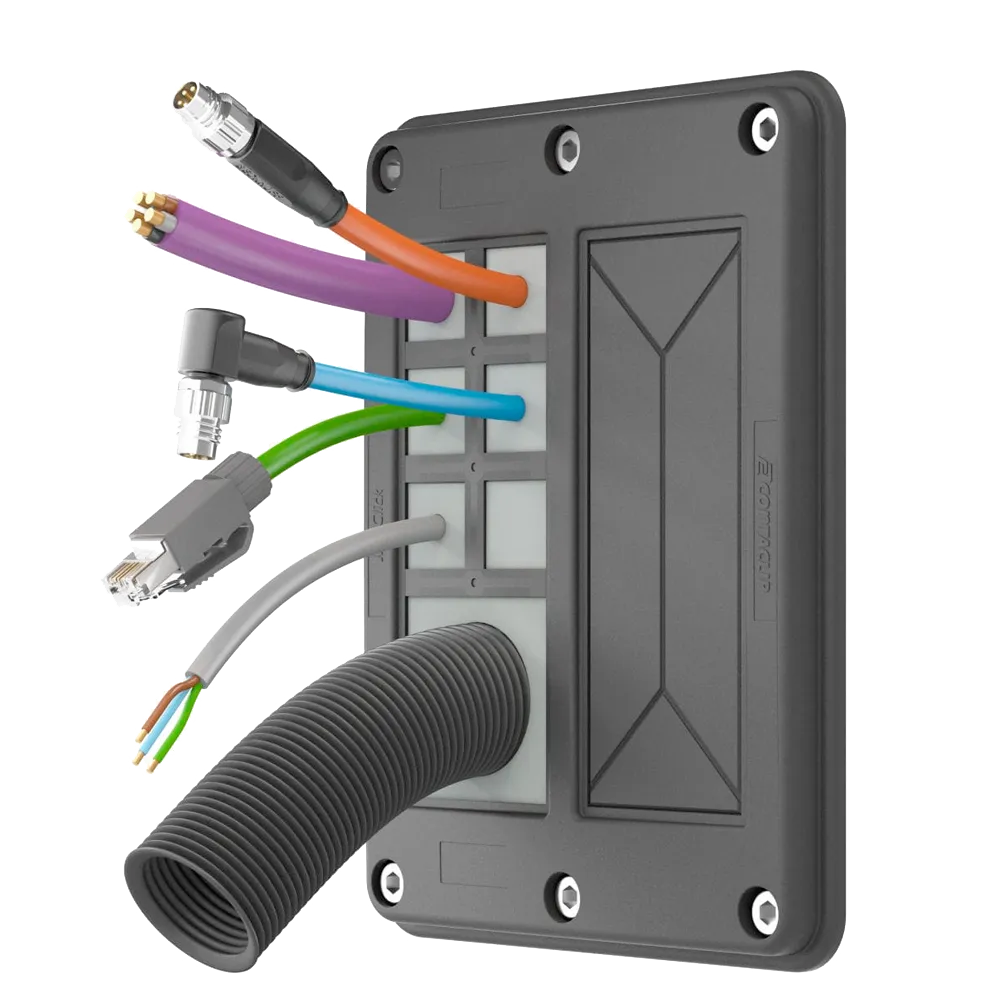

COMBI Plug in Connection

Uniform plug in zone enabling connectors and terminal blocks across four technologies to be freely combined.

Best for modular machines and areas requiring quick component changes.

RT Bolt Connection

Robust terminations for ring lug conductors, combined with CLIPLINE’s bridging, testing and marking advantages.

Best for heavy duty applications requiring high mechanical stability.

Why mixing technologies in one system improves flexibility

Most terminal strips need more than one connection method. CLIPLINE complete enables switchboard builders, panel builders and OEMs to match each technology to the application while still working within a unified accessory and assembly system.

For example:

PT for fast control wiring

PTV for lateral entry in tight spaces

UT for higher current circuits

ST for vibration prone sections

QT where rapid wiring is required

RT for ring lug connections

COMBI for modular assemblies

This level of flexibility supports a wide variety of wiring requirements while keeping the overall system consistent.

PROJECT complete more accurate and consistent planning

Terminal strip planning can become complex when different terminal families and accessories must be manually coordinated. PROJECT complete configuration software supports users by helping design and document terminal strips in a structured and consistent way.

Benefits include:

clearer planning and documentation

easier accessory selection

repeatable layouts across similar projects

When combined with the standardised CLIPLINE complete platform, it helps teams maintain accuracy and consistency from design through to assembly.

What this means for switchboard builders, panel builders, OEMs and electricians

CLIPLINE complete provides a unified and flexible terminal block system that simplifies assembly and supports a wide range of project requirements. With one accessory interface and compatibility across seven connection technologies, teams gain:

fewer accessory variations

consistent assembly methods

a more streamlined approach to building terminal strips

flexibility to choose the right connection technology for each application

For organisations seeking a more efficient and consistent terminal block approach, CLIPLINE complete offers a system level solution that supports diverse project needs without adding complexity.