Is Cable Failure Slowing Down your Production?

Industrial environments place tremendous stress on cables - frequent bending, twisting, abrasion, exposure to oils, and chemical contact can all cause premature wire failure.

When a cable breaks in high-motion applications, it can mean hours of downtime while you troubleshoot, remove, and replace components.

The good news? Excessive cable failures don’t have to be the norm.

Enter Banner Engineering’s High Flex Cordsets featuring HighFlex20™ technology - a durable, cost-effective solution designed to keep your operations running without interruption.

Why High Flex Matters

Many industries, including OEM manufacturing, mining, defence, aviation, and industrial R&D, rely on continuous movement in their equipment.

Servo gantry systems are a prime example. These systems typically involve a gripper or end effector that moves along multiple axes - X, Z, and often Y. Sensors and feedback devices on these end effectors require cables that can flex constantly. A typical cable might withstand initial use, but after repeated bending, it begins to break down. This is inconvenient in a stationary setup, but in an integrated machine with a cable track, replacing the cable can be a major ordeal - one that can shut operations down for hours.

HighFlex20™ Technology

Banner’s HighFlex20™ technology is engineered to endure up to 20 million bend cycles. Instead of constantly worrying about broken cables, machine operators and maintenance professionals can rest assured that their setup is built for the long haul. This dramatically reduces the risk of unplanned downtime, and it means more productive hours on your manufacturing or processing line.

Key Features and Benefits

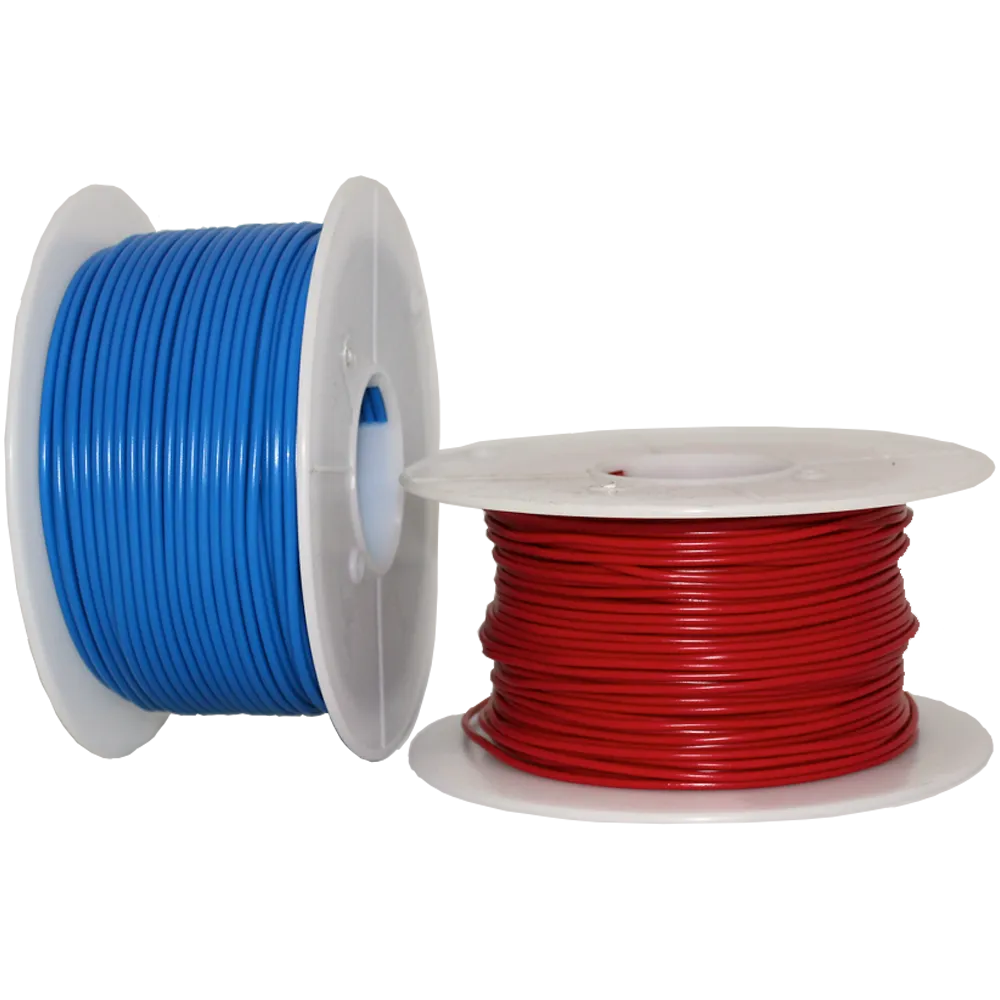

1. Reinforced PVC Jacket: HighFlex20™ cables are jacketing with PVC that guards against oils, chemicals, and abrasion. In harsh industrial environments, standard cables can deteriorate quickly, but these specially designed cordsets stand up to daily punishment.

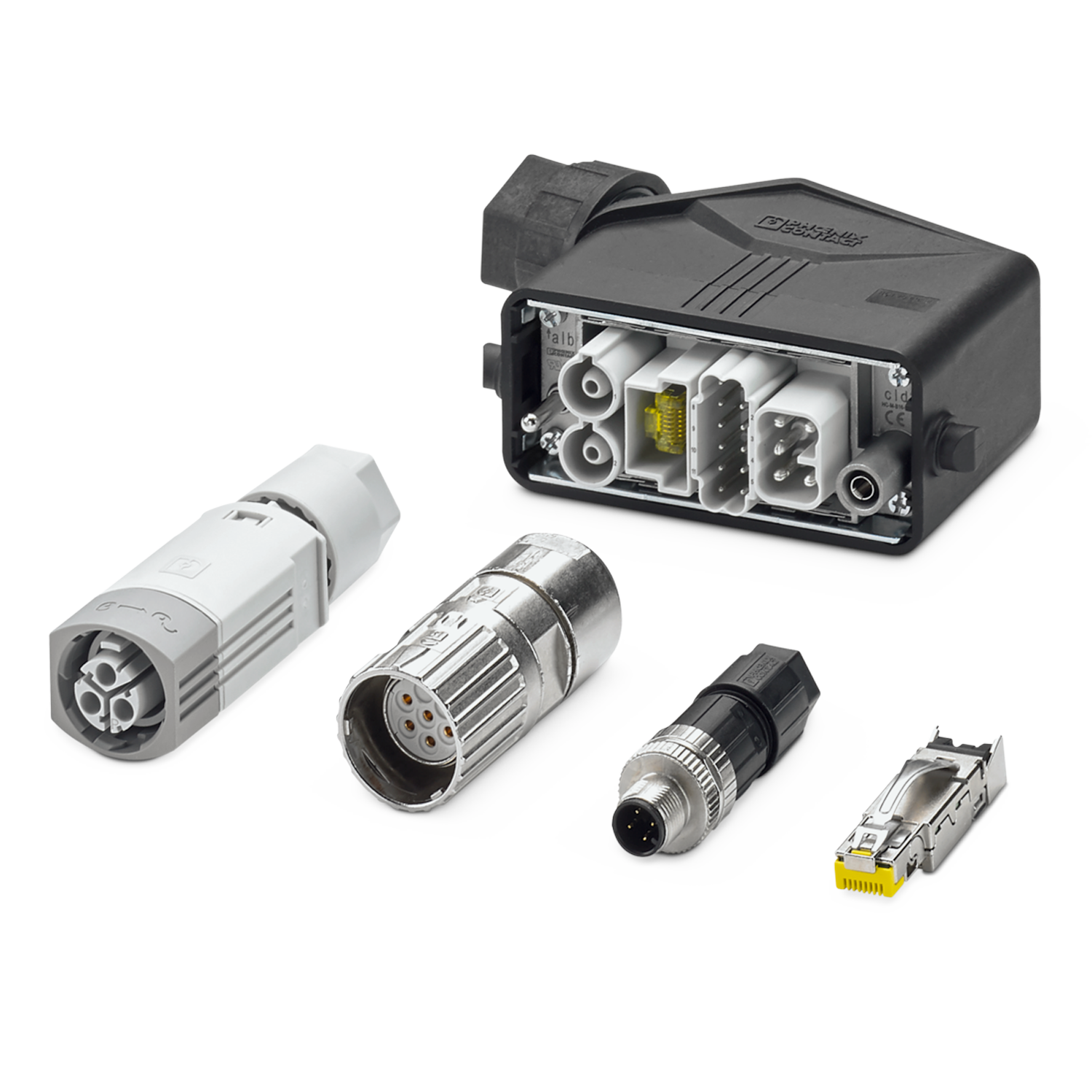

2. M8 and M12 Connectors: Available in both straight and right-angle configurations, the vibration-resistant overmolded connectors are built to maintain strong electrical connections - even in the face of repeated motion and heavy vibration.

3. Versatile Configurations: Whether you need single or double-ended cables, male or female connectors, or lengths from 1m to 15m, Banner’s high-flex series has you covered. With only four-pin connectors and four-conductor cables, it’s streamlined to match common industrial sensor and actuator requirements.

4. Easy Installation: The cordsets are designed for rapid setup, saving both time and labour costs. Their user-friendly design means you can simply plug them in, route them through your equipment, and get back to work.

5. Reduced Maintenance Costs: Fewer cable failures mean fewer moments of downtime and lower repair bills. For many businesses, the cost of lost production can easily outweigh the cost of cables. By investing in a robust, high-flex solution, you’re investing in long-term reliability.

Applications that Demand High-Flex Reliability

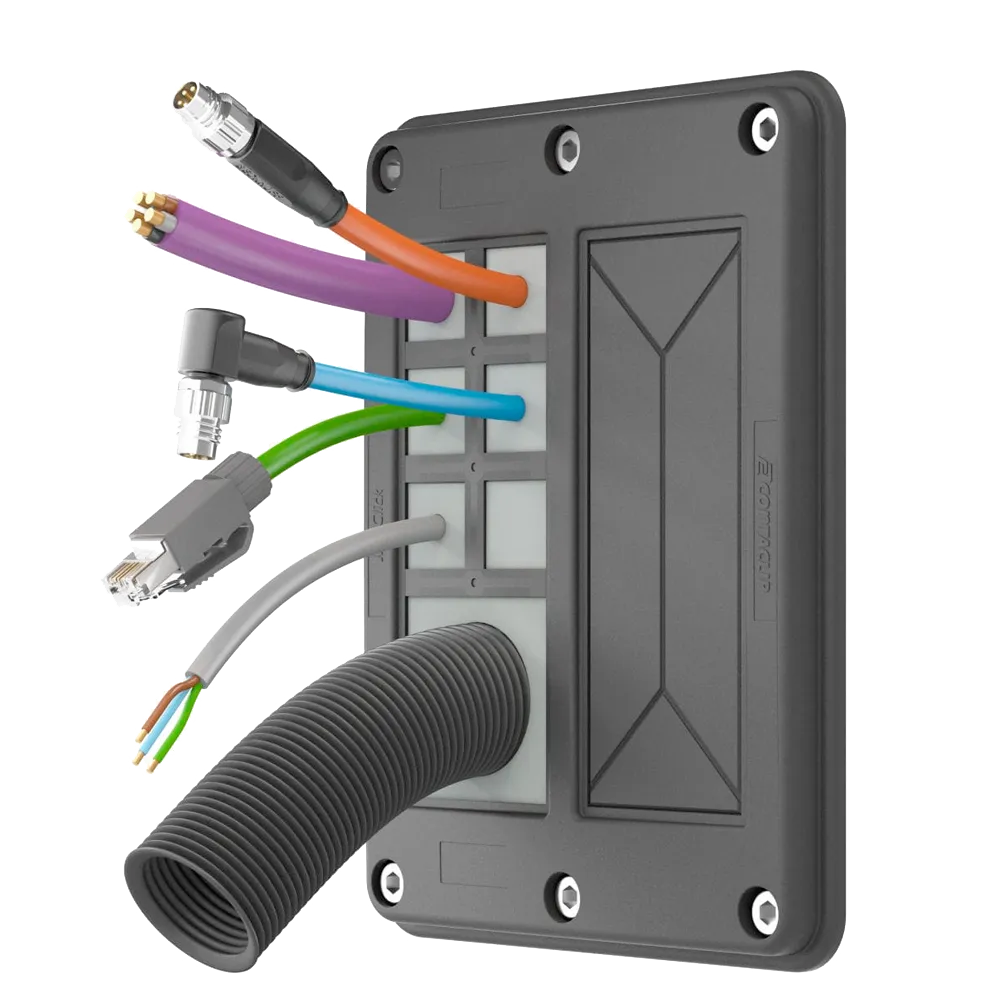

• Servo Gantry Systems: For X-Y-Z motion, the end effector’s cable track experiences constant bending. HighFlex20™ keeps you in operation longer by withstanding that repeated stress.

• Robotics: Robotic arms and automated tooling often rotate and articulate through extreme angles. HighFlex20™ cables maintain signal integrity throughout these movements.

• Cable Track Systems: Whether you’re running cables through a track on a conveyor or a piece of automated machinery, these cordsets resist twisting and pulling cycles that would wear down standard cables.

• Linear Actuators: When actuators extend and retract, cables must handle cyclical motion. With Banner’s specialised design, stress is minimised, protecting the cable’s core and reducing failures.

A Reliable Option in Tough Environments

In many industries, unplanned downtime can mean losses in production worth thousands, or even millions, of dollars. When every minute counts, you want a product that can handle the rigors of your operation.

HighFlex20™ technology was created with harsh manufacturing conditions in mind, ensuring that your cables can endure the environment rather than succumb to it.

By choosing Banner Engineering’s High Flex Cordsets with HighFlex20™ technology, you gain fewer cable failures, less downtime, and a rugged connection that resists oils, chemicals, and abrasions - ensuring your operations run smoothly, efficiently, and cost-effectively.