Why Coordinated Power and Surge Protection Matters

Transient electrical stress is one of the main factors that limits power supply service life in industrial systems.

How that stress is handled at the power supply level has a direct impact on long term reliability and system availability. This depends not only on the presence of surge protection, but on how closely it is coordinated with the power supply itself.

This is where a system level approach to the power path becomes important.

Designing the power path as a system

System availability is influenced by more than steady state electrical performance. Transient overvoltages, switching events, and EMC disturbances impose repeated stress on power supplies throughout their service life.

When surge protection and power supplies are selected independently, surge currents can be unevenly distributed during transient events. This concentrates stress on internal power supply components, accelerating ageing and increasing the risk of failure over time.

Coordinated design treats surge protection as part of the power supply strategy rather than an isolated protective measure.

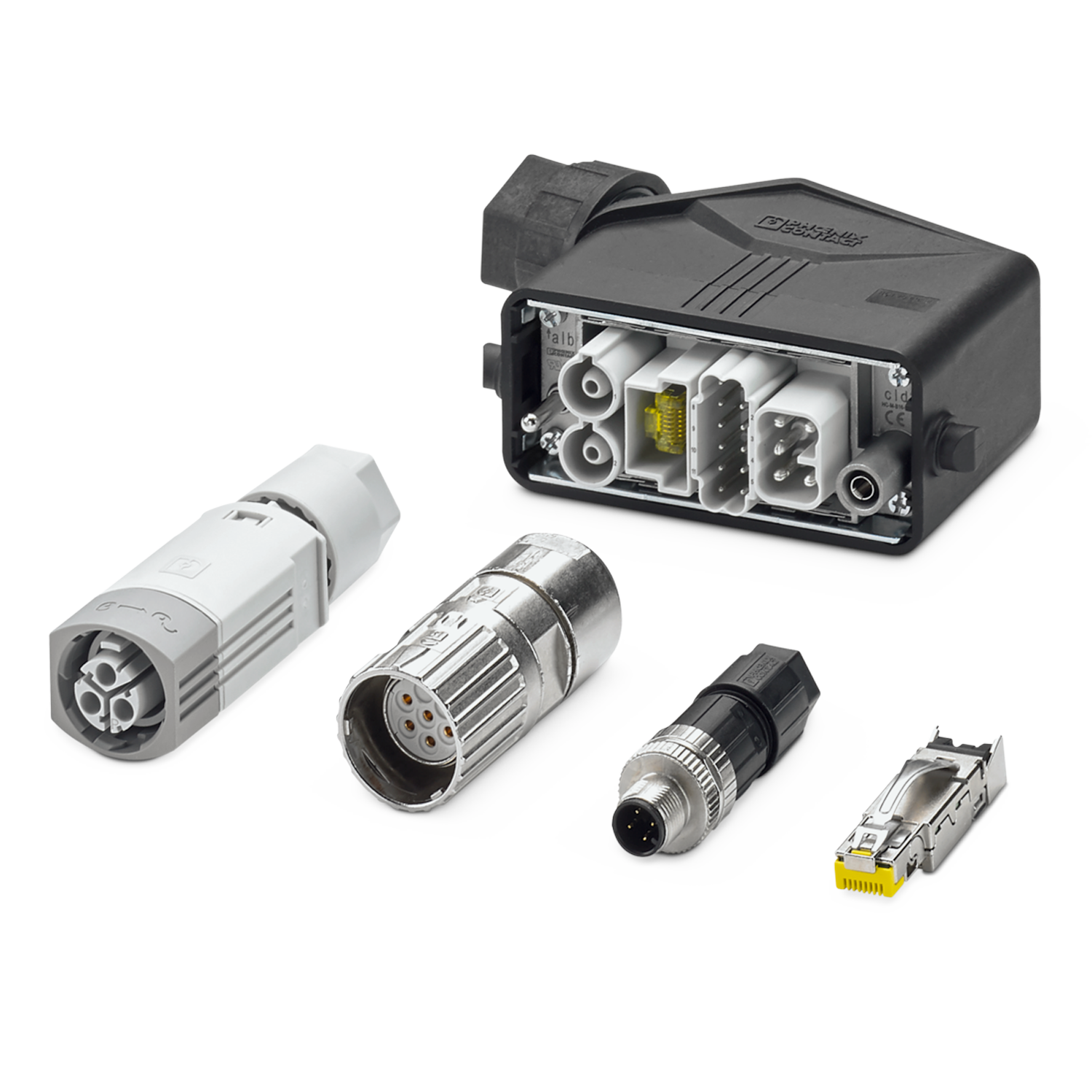

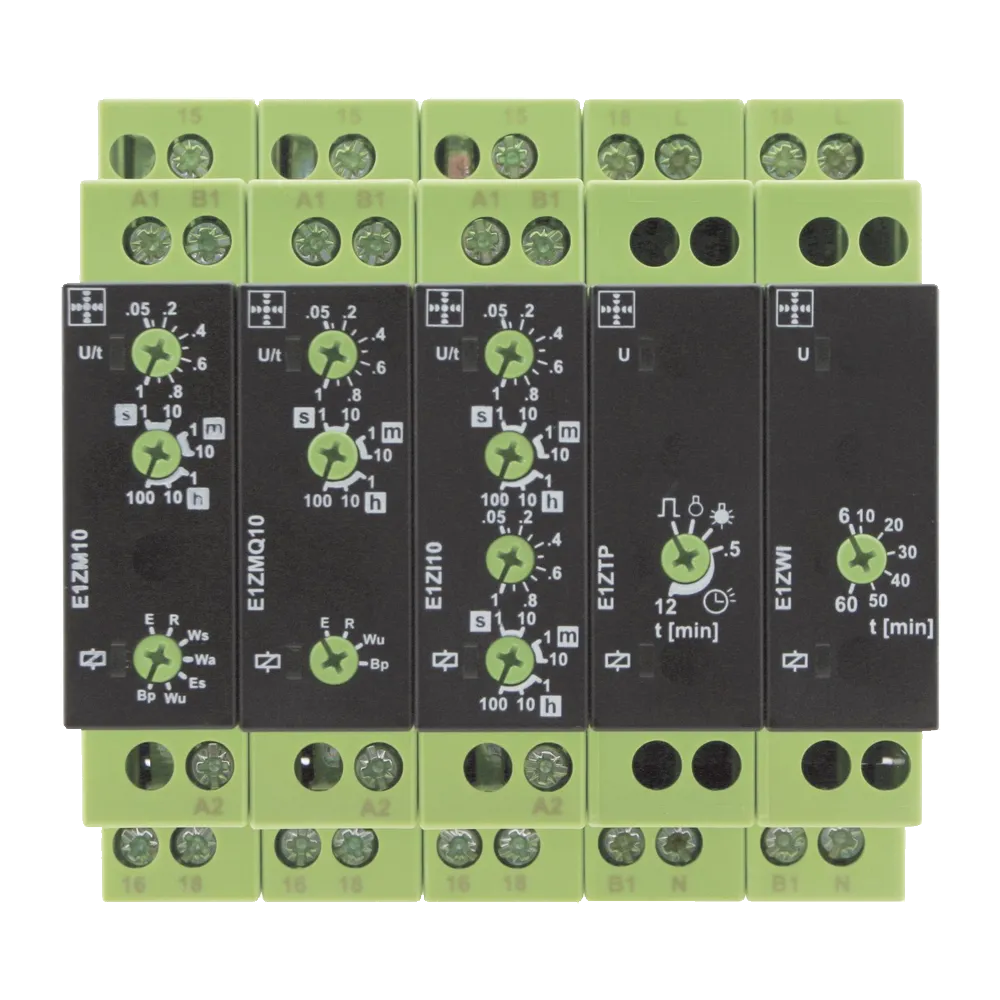

The coordinated pairing: QUINT POWER and PLT-SEC

Phoenix Contact has addressed this interaction by optimising the coordination between the QUINT POWER power supplies and the PLT-SEC surge protection range.

This combination is designed so that, when an overvoltage occurs, surge currents are distributed symmetrically and controlled before they reach sensitive electronics within the power supply.

The outcome is reduced electrical stress at the point where long term reliability is most affected.

What coordination changes in practice

Higher surge withstand capability

When a PLT-SEC type 3 surge protective device is used in front of a QUINT POWER power supply, the power supply can withstand surge currents up to ten times higher than it could without coordinated protection. This improvement reflects how the two products behave together during transient events.

Extended power supply service life

By limiting the electrical stress imposed on internal components, the coordinated combination effectively doubles the expected service life of the power supply compared to non harmonised solutions. For continuously operating systems, this has a direct impact on long term reliability and maintenance planning.

Improved planning certainty

When used as an intended combination, the coordinated design supports extended warranty coverage, providing greater confidence during specification and project planning.

Why this matters for system availability

Unplanned downtime is rarely caused by a single extreme event. More often, it results from cumulative degradation due to repeated electrical stress over time.

High EMC environments, frequent switching loads, and transient disturbances are part of normal industrial operation. Designing for availability means accounting for these conditions at the power supply level, not just at the system boundary.

Coordinated surge protection and power supply design helps reduce premature ageing, lowers the risk of intermittent faults, and supports predictable long term system performance.

Supporting features that reinforce reliability

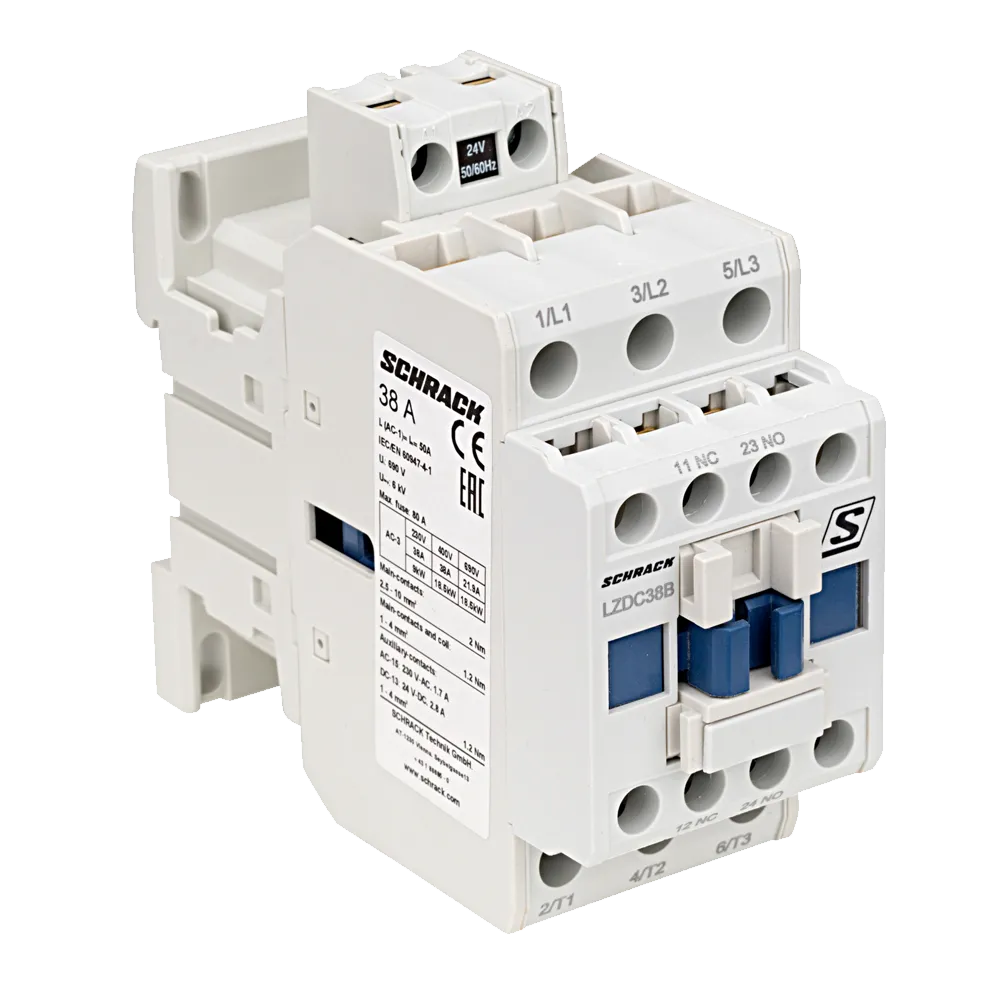

The QUINT POWER power supply includes functions intended to support demanding industrial applications, including:

Selective Fuse Breaking technology for reliable downstream circuit protection

Static and dynamic power boost to manage load peaks

Preventive function monitoring to support maintenance planning

Availability of individual solutions starting from a batch quantity of one

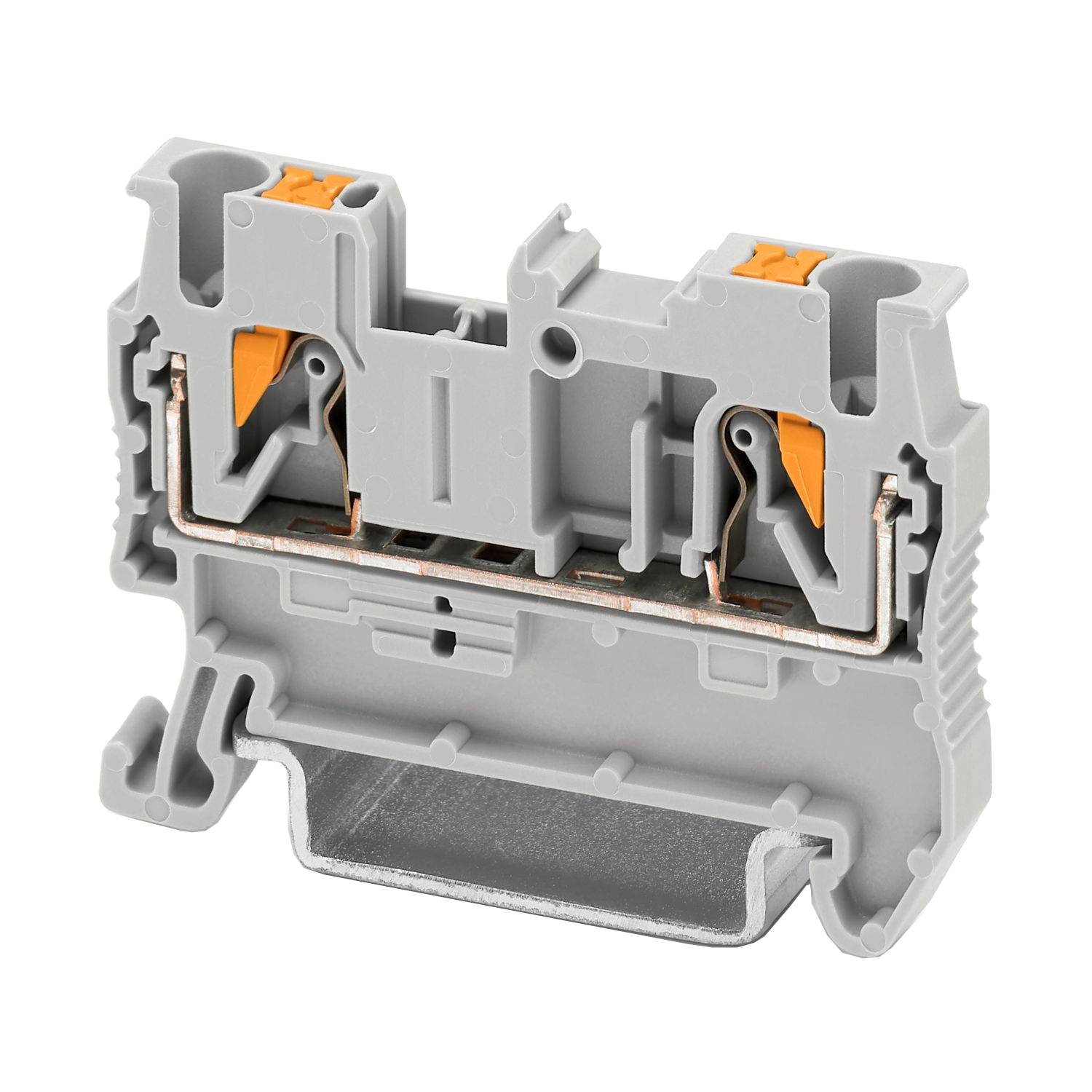

The PLT-SEC surge protection range complements this with:

Protection for end devices close to the load

Multiple connection technology options

Local status indication and remote signalling contact

Pluggable, testable design to support maintenance and replacement

Individually, these features address specific requirements. Together, they support a more resilient power architecture.

A design decision, not an add on

Coordinating surge protection with the power supply reduces system risk by ensuring components behave predictably under electrical stress.

For engineers and panel builders focused on long term system availability, the QUINT POWER and PLT-SEC combination illustrates how treating the power path as a coordinated system can deliver measurable reliability benefits over the life of an installation.