Phoenix Contact Terminal Blocks

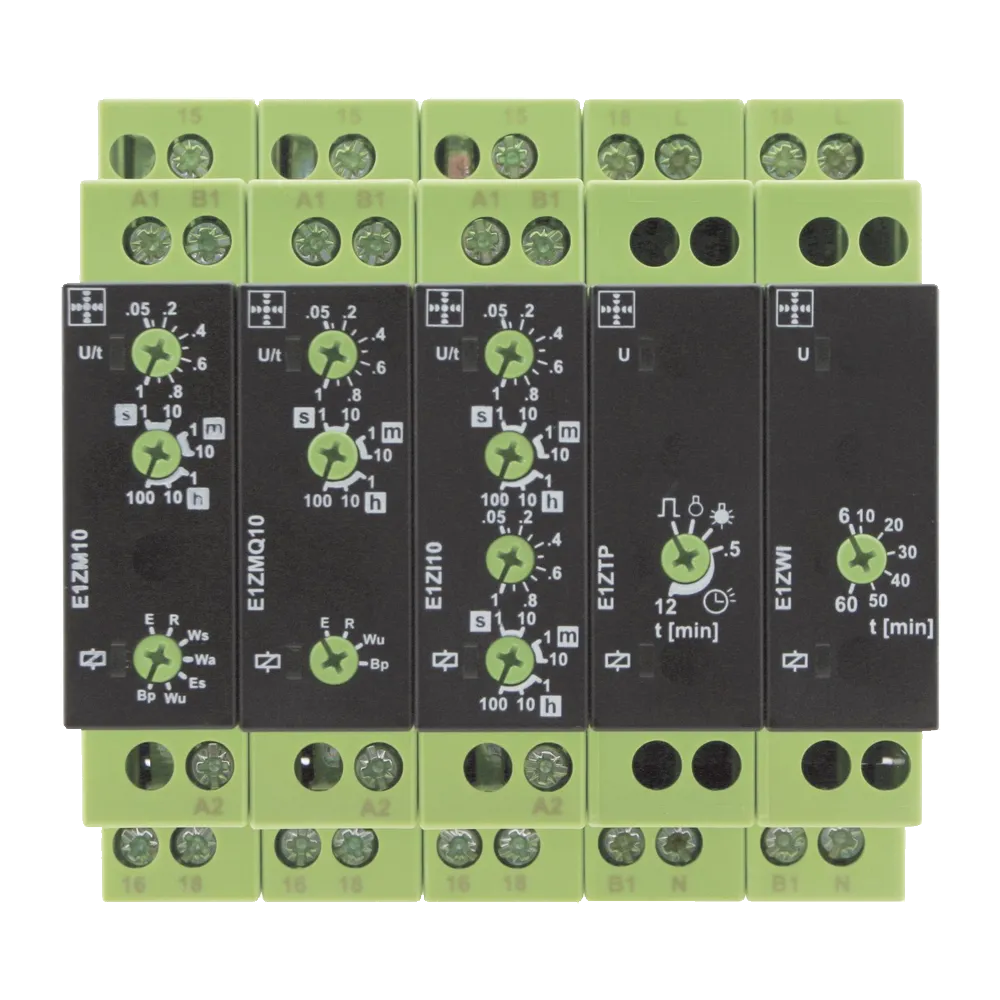

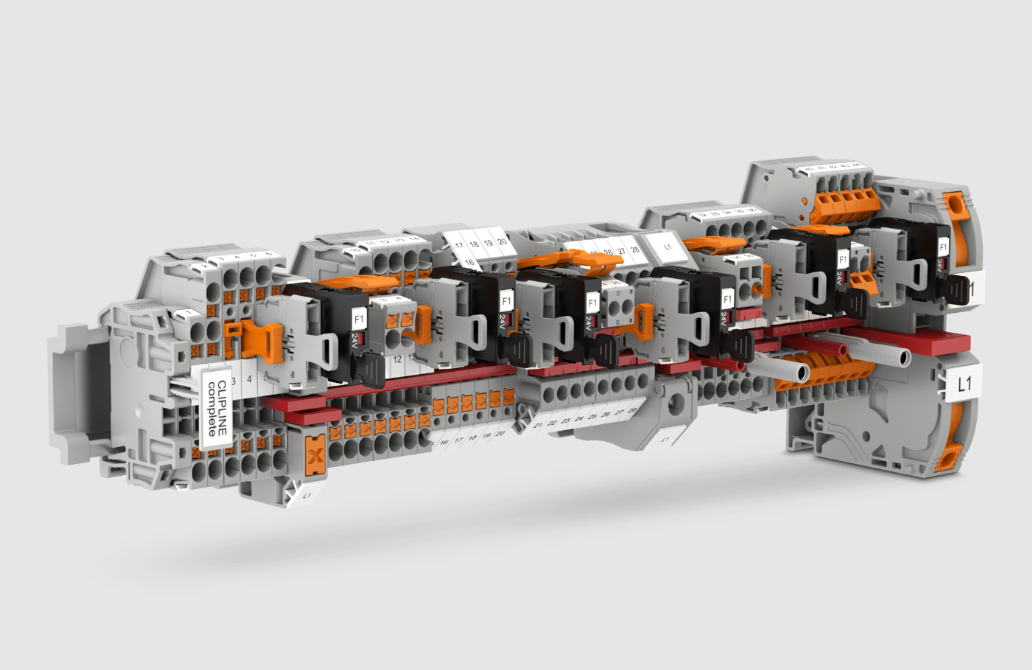

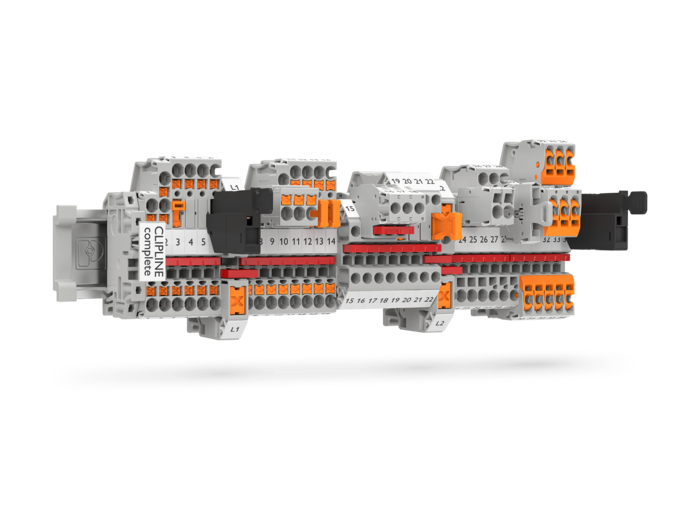

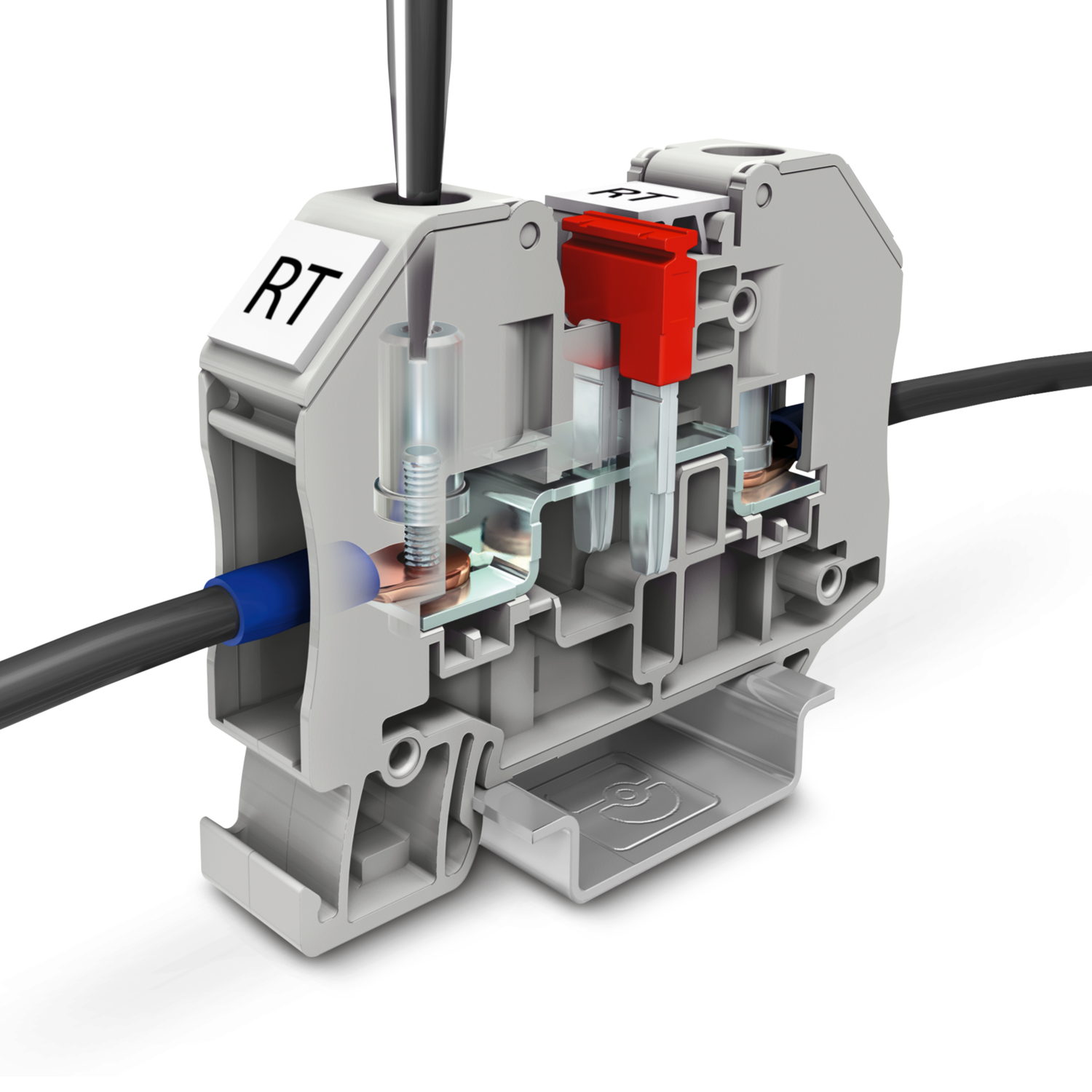

The Phoenix Contact terminal blocks enable a high degree of flexibility in terminal strip design. Choose between various connection technologies and combine the terminal blocks by installing bridges in the double function shaft. The terminal block system features standardized bridging, marking, and test accessories.

Your advantages

Complete flexibility: Terminal blocks with different connection technologies can be freely combined

Bridging and testing option with double function shaft

Additional test option with integrated test points, eliminating the need for removing conductors or bridges

Save money with uniform bridging, marking, and test accessories

Extensive digital data

Terminal blocks exceed the requirements imposed by standards

The terminal blocks from Phoenix Contact have been tested and approved for a wide range of national and international approvals. The terminal blocks are very resistant to environmental influences and feature a high level of long-term stability and long-term reliability. The terminal blocks exceed the requirements imposed by standards in various industries with their material properties and their electrical and mechanical properties. The terminal blocks are tested throughout the entire manufacturing process to ensure that this level of quality is consistently maintained.

Read more by downloading Phoenix Quality Brochure

Connection technologies included in the CLIPLINE system

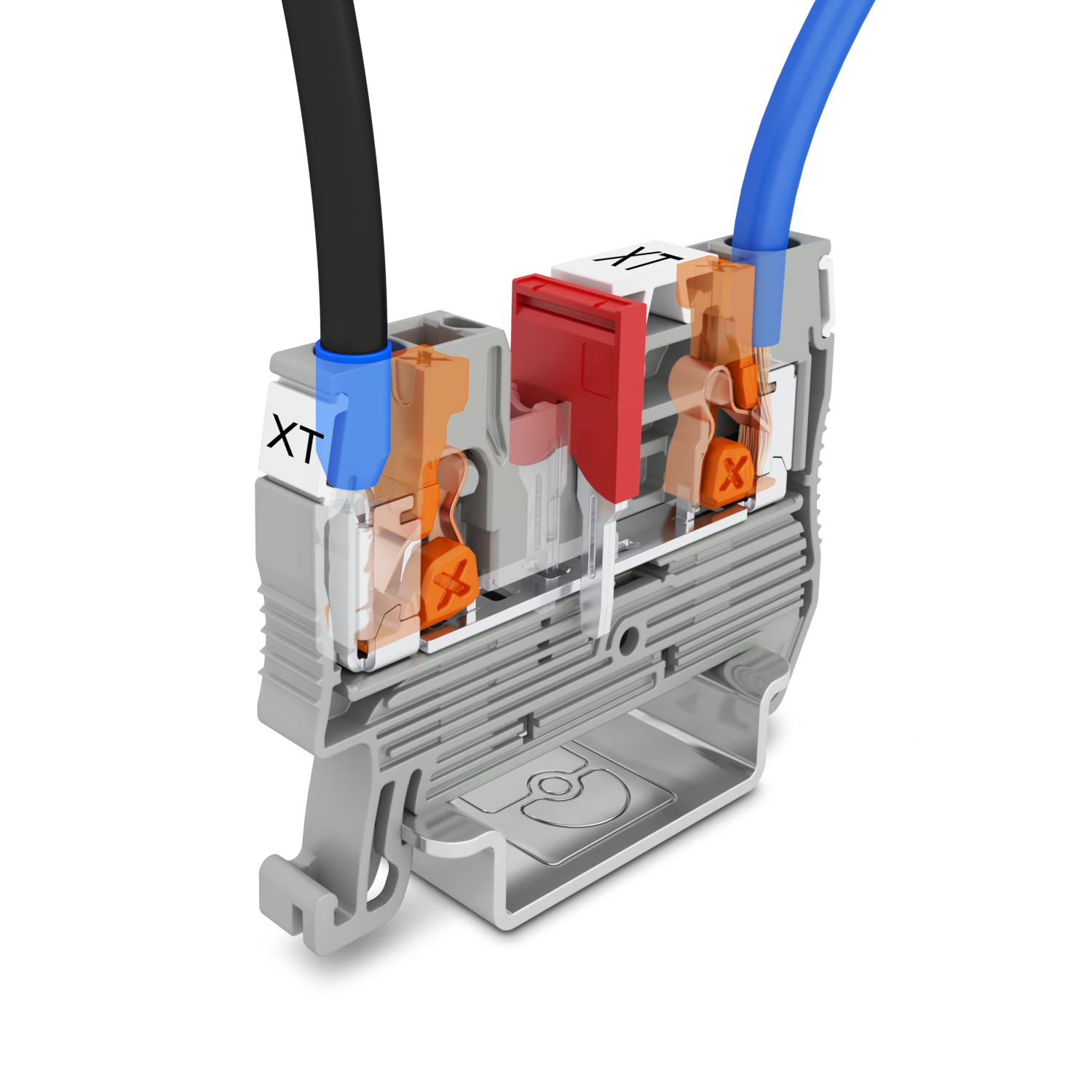

Push-X Connection Technology

The XT terminal blocks with Push-X technology enable easy connection of rigid and flexible conductors with or without ferrules. Even small and flexible conductors can be clamped quickly and easily with the pretensioned contact chamber. Simply insert the conductors to the end of the chamber. Pressing down the locking mechanism at the end of the chamber releases the contact spring and snaps it shut rapidly. The XT terminal blocks are initially available with a nominal cross-section of 2.5 mm².

Tool-free conductor connection reinvented: Push-X allows direct wiring of rigid and flexible conductors with or without ferrule with the pre-tensioned contact spring. Insert the conductor up to the end of the clamping chamber without effort. As soon as the conductor pushes down the contact spring’s locking mechanism in the end position, the slider is released and the contact spring snaps automatically. The conductor is clamped directly during this process. Like with the well-known Push-in technology, the conductor is released via the orange push button. At the same time, the contact spring is preloaded for the next wiring process.

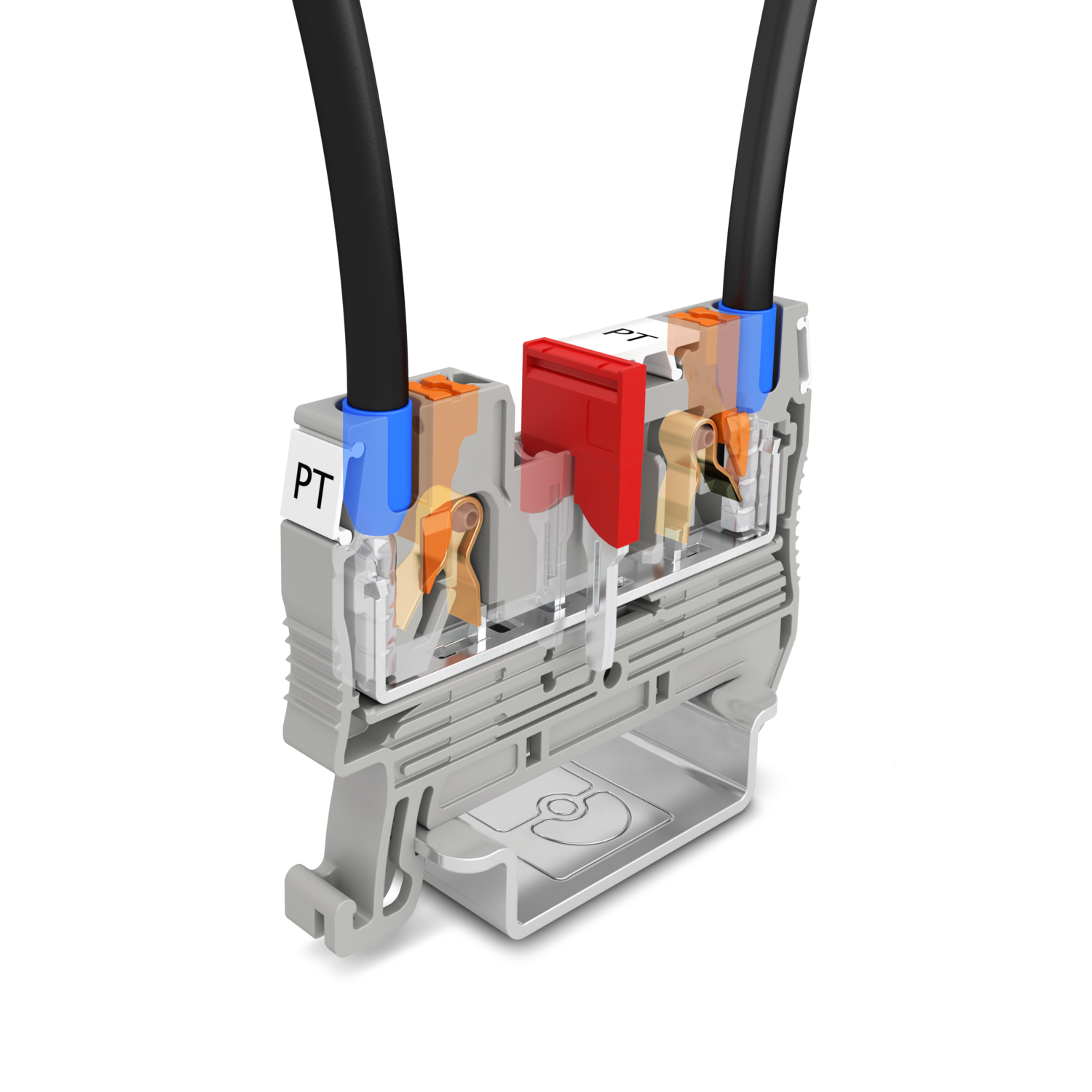

Push-in Connection Technology

With PT Terminal blocks with Push-in connection technology, you can connect conductors from 0.25 mm² easily – both directly and without tools. The special terminal block contact spring enables up to 50% lower insertion force. Other features include the high contact quality and high conductor pull-out forces. Push-in technology is available for conductor cross-sections up to 185 mm².

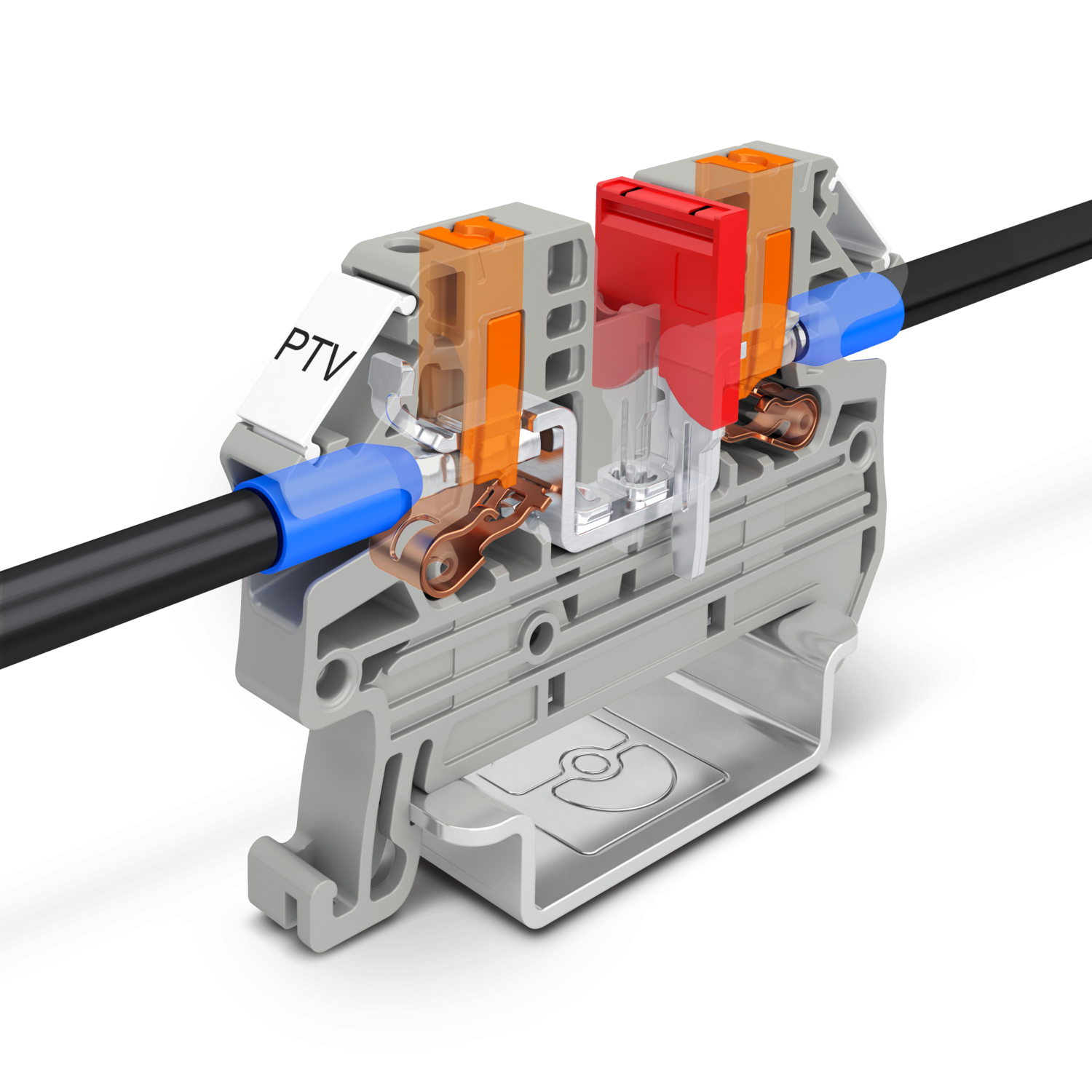

Lateral Push-in Connection Technology

The PTV terminal blocks from Phoenix Contact have a lateral Push-in connection. The connection combines the lateral conductor routing of a screw connection with the tool-free direct connection technology of a Push-in connection. The terminal blocks therefore combine the advantages of both connection technologies. This ensures clear and fast wiring without bending radii.

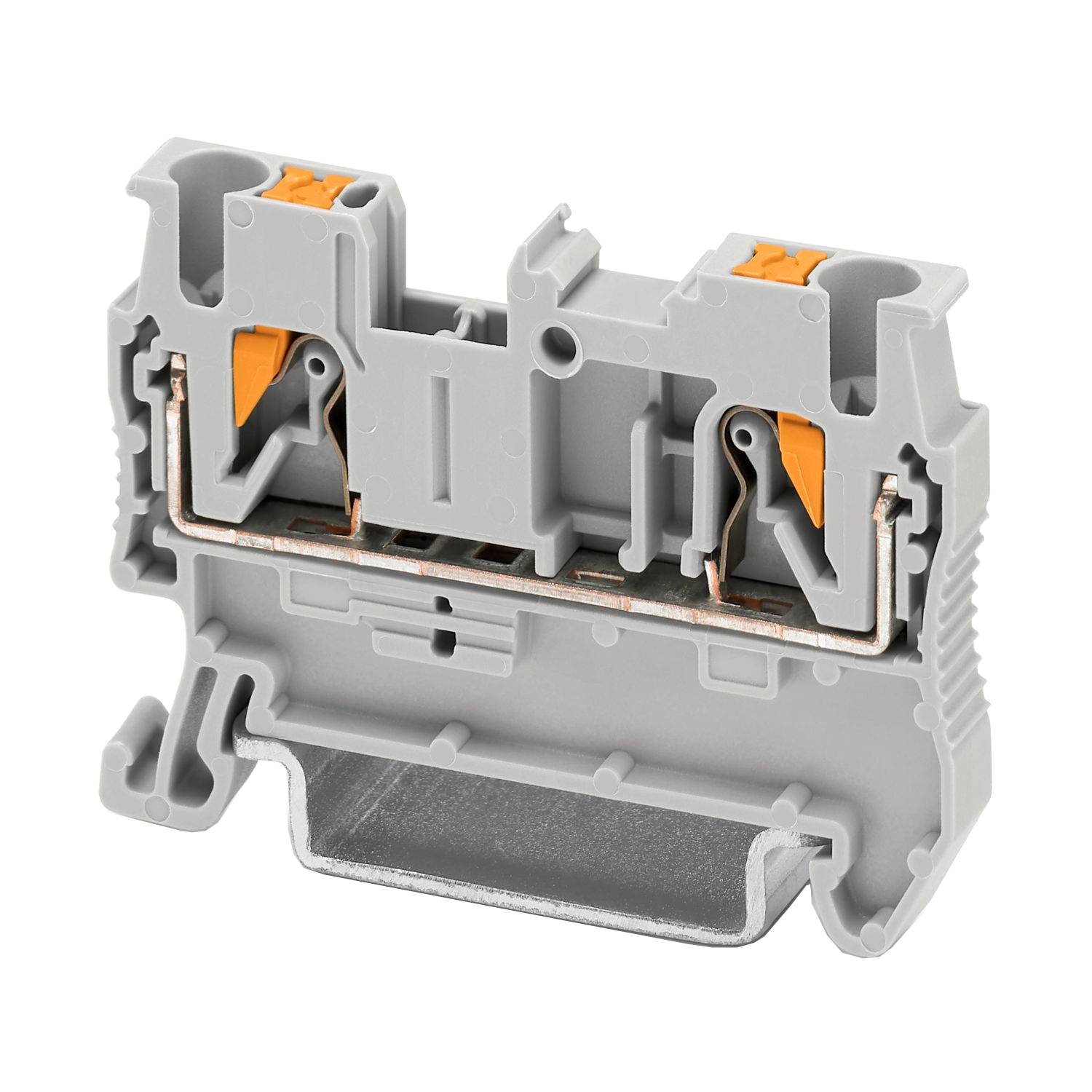

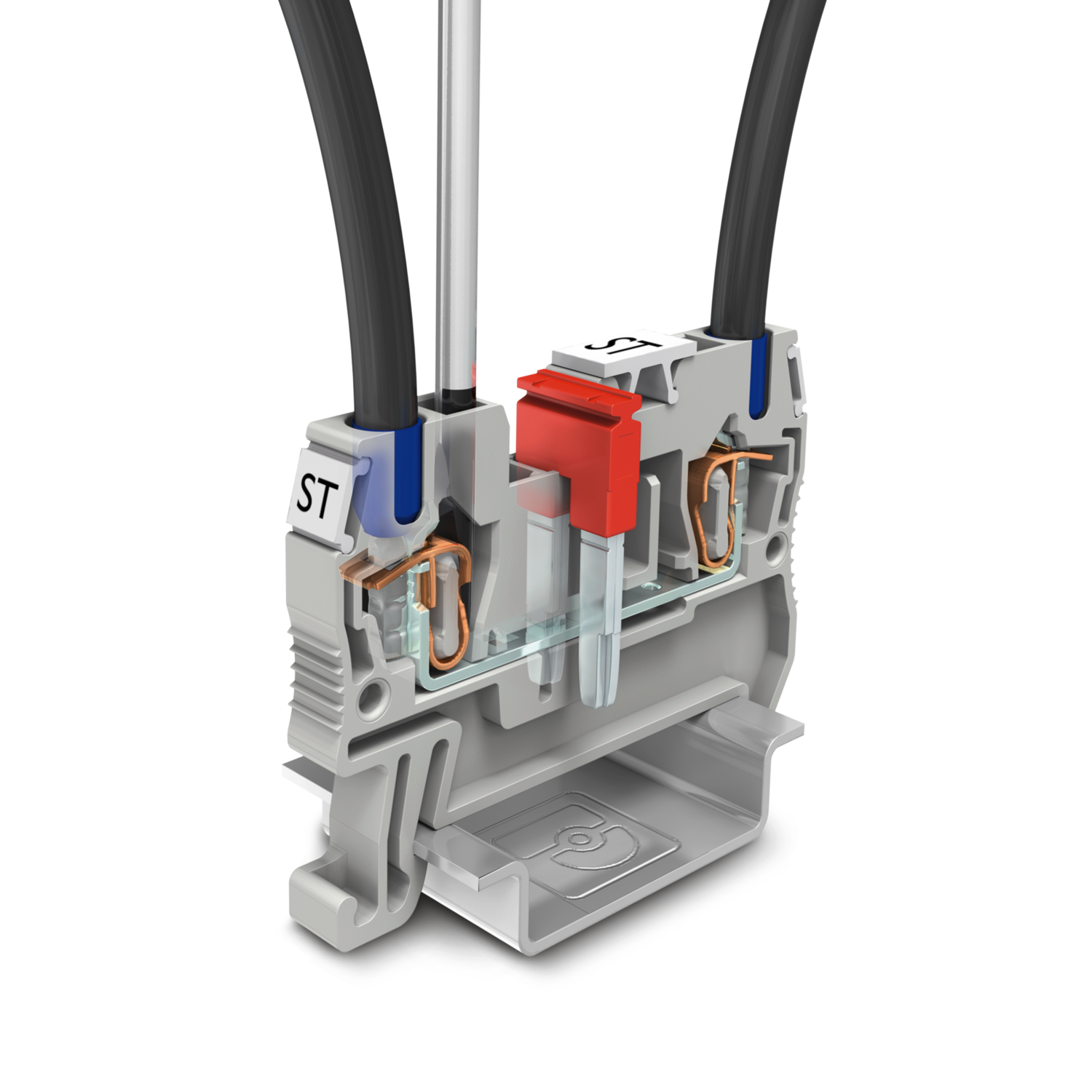

Spring Cage Connection Technology

The ST terminal blocks with spring-cage connection are particularly suitable for vibration-sensitive applications. The constant spring force means that the terminal blocks provide high contact reliability independent of the operator. The terminal points on the spring-cage terminal blocks can be opened easily with a screwdriver. The terminal blocks are available up to a cross-section of 35 mm².

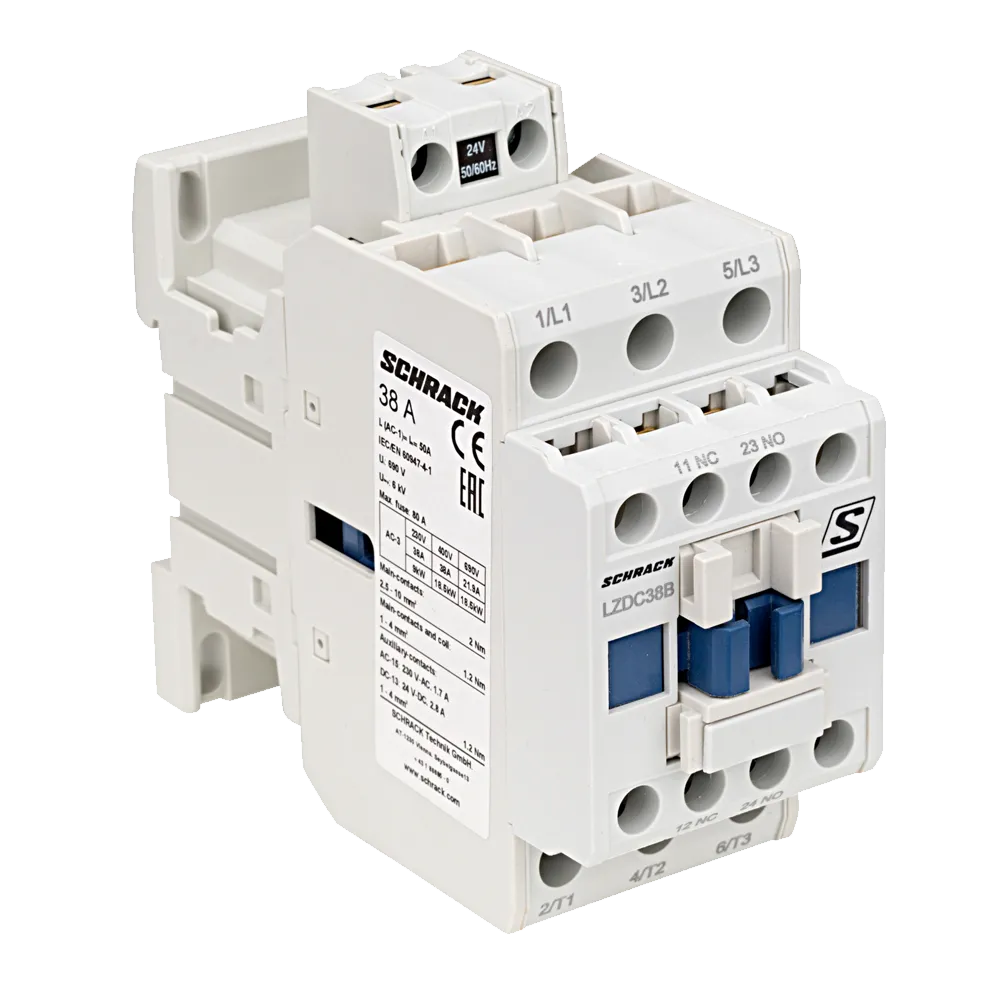

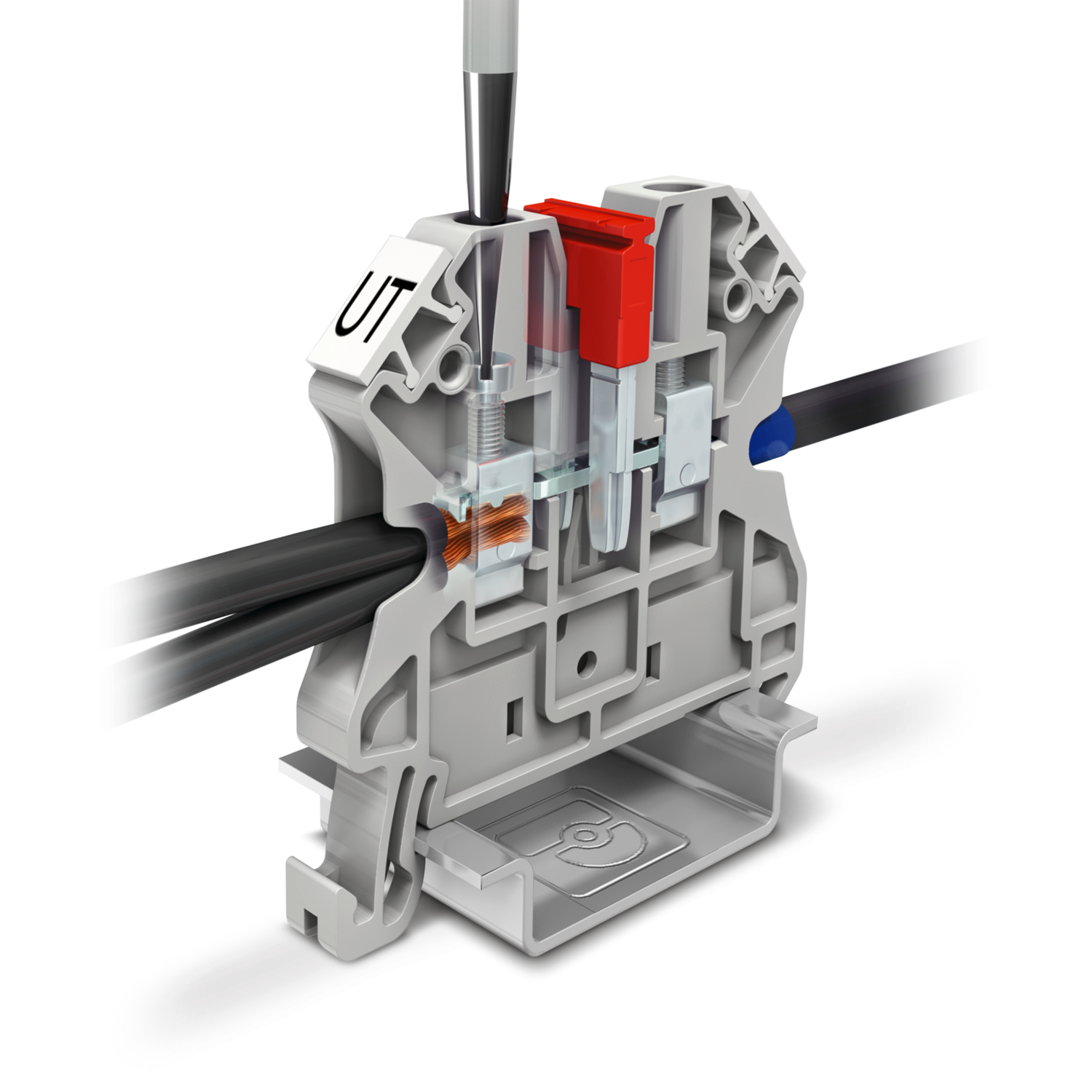

Screw Connection Technology

The UT terminal blocks with screw connection technology have been known and accepted worldwide for over 80 years. The screw connection provides maximum contact force and is maintenance-free thanks to the Reakdyn principle. The terminal blocks allow multi-conductor connection at just one terminal point. Connect copper conductors with up to 240 mm² cross-section without any pretreatment.

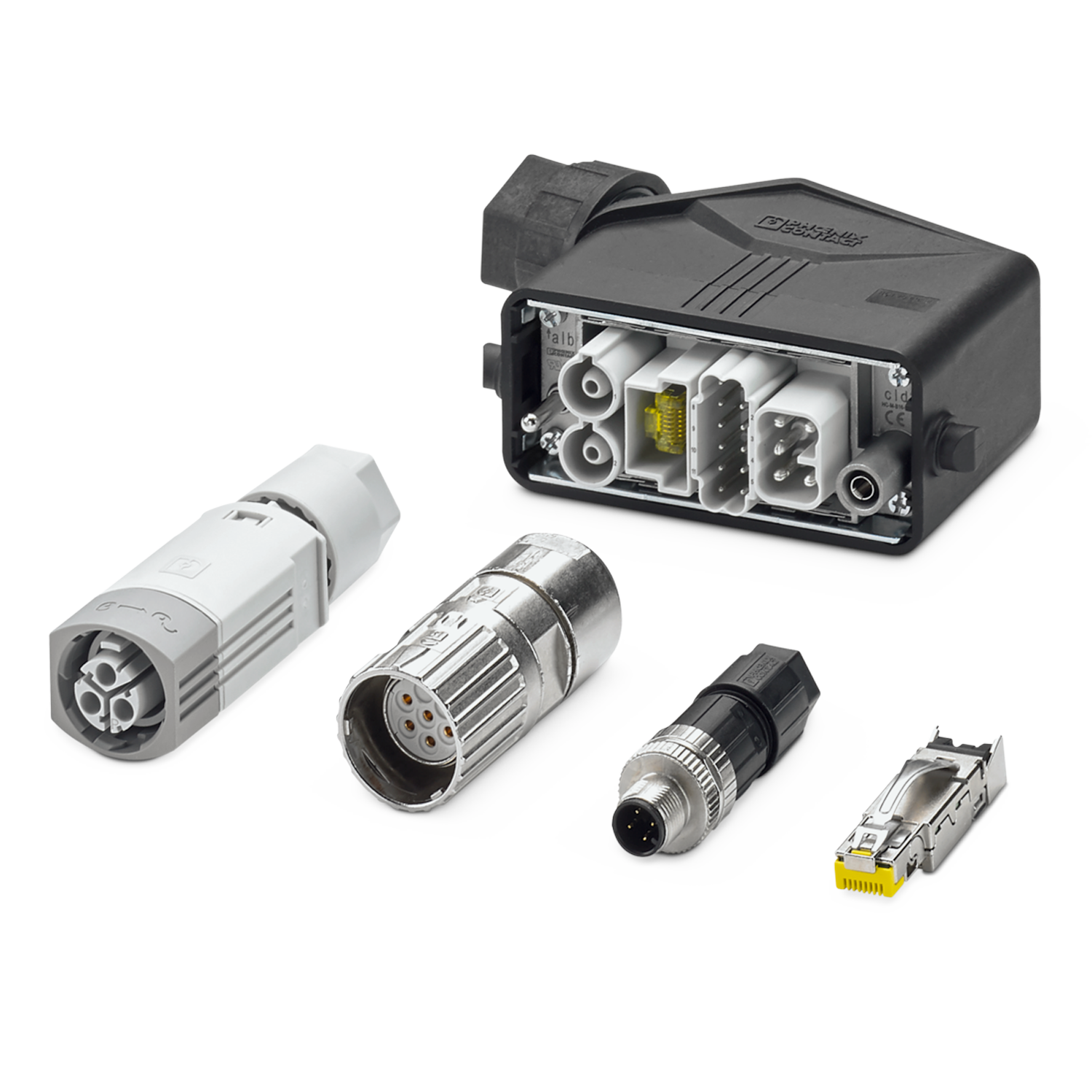

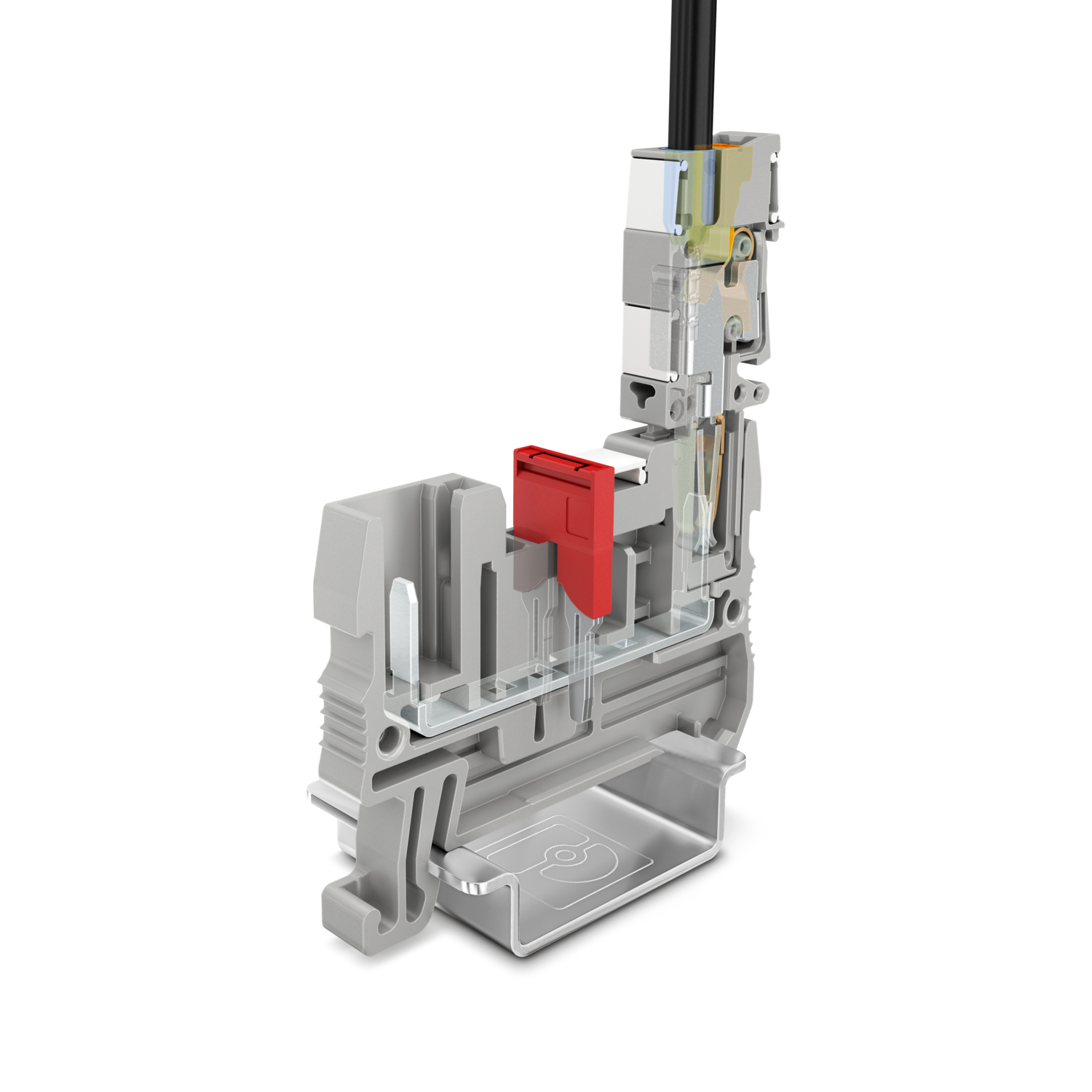

Plug-in COMBI Connection

Terminal blocks with COMBI connection are designed for stringent and universal requirements.

The nominal current is routed to the terminal blocks via the contact pin. In conjunction with the contact system in the connector, the connection versions can withstand extreme vibration levels. The COMBI terminal block connection is suitable for your automated, semi-automated, or manual wiring tasks.

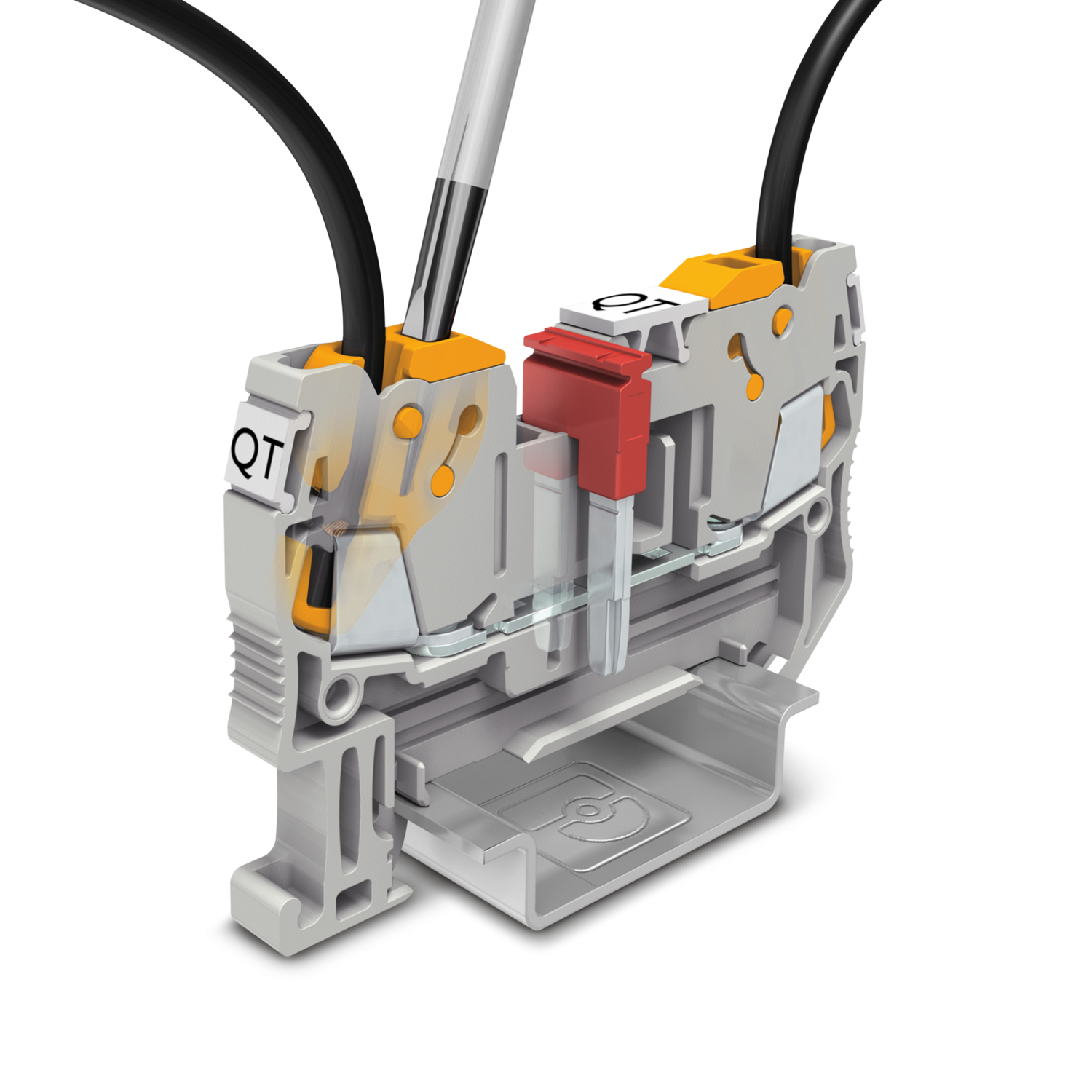

Fast Connection Technology

The terminal blocks with fast-connection technology feature a patented insulation displacement contact that can be operated with the space-saving swiveling lever using a screwdriver.

The insulated, non-pretreated conductor is connected in just one step.

The resulting time savings can be up to 60%. Due to the available cross-sections of up to 4 mm², the terminal blocks are suitable for control current wiring in the control cabinet.

Bolt Connection

The terminal blocks with bolt connection are suitable for connecting ring and fork-type cable lugs. The connection allows for considerable conductor pull-out forces due to the high contact force and the large contact surfaces. Terminal blocks with bolt connections allow multi-conductor connection at just one terminal point. The captive cap nuts on the hinged covers are an additional advantage.

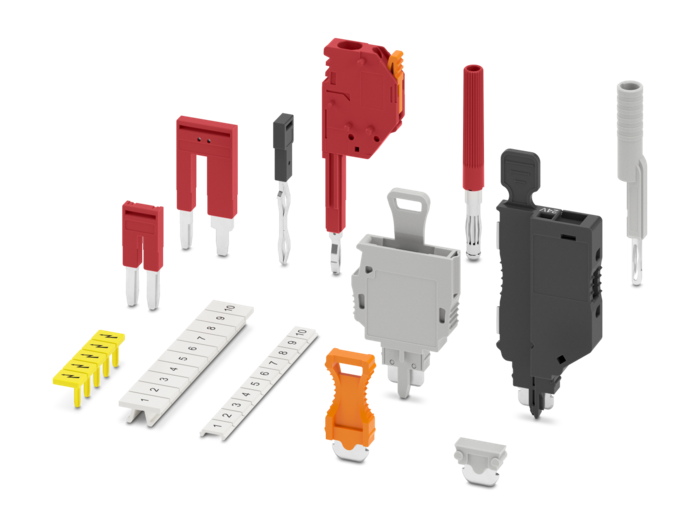

Standardized accessories for terminal blocks

The standardized accessories of the CLIPLINE complete terminal block system include a variety of different products. In addition to standardized bridging, testing, and marking accessories, the range also includes more special accessories such as pick-off plugs, function plugs, and service plugs.

Brochures about terminal blocks

Would you like to get printed information about our terminal blocks? Below you will find various brochures on the subject of terminal blocks and marshalling panels. In addition to the product brochures, you will find a brochure about the CLIPLINE complete terminal block system and about the quality tests for the terminal blocks.