Techno Connectors now available in overmoulded versions

Industrial automation, lighting and other industries and applications often require cables that can withstand bending and repeated disconnections.

Techno responds to these needs with ready-to-use solutions for connectors and cables, in which their union is given by a glue that is overprinted on the connector and the cable through a specific vertical injection process, ensuring chemical and mechanical fusion between cable and connector.

In particular, the material used consists of special sealing resins and Hot-Melt polyamides, whose characteristics of resistance to UV rays, adverse weather conditions, as well as durability over time, ensure compliance with the high quality standards of the Techno offer. The result is therefore a unique piece, without gaskets or cable glands.

High Quality Sealing of IP68 Connectors

Techno uses a special injection process for the overmoulding that ensures the chemical and mechanical fusion of the adhesive between the cable and the connector. In addition, the special sealing resins provide a durable solution and optimum resistance to UV rays and adverse weather conditions.

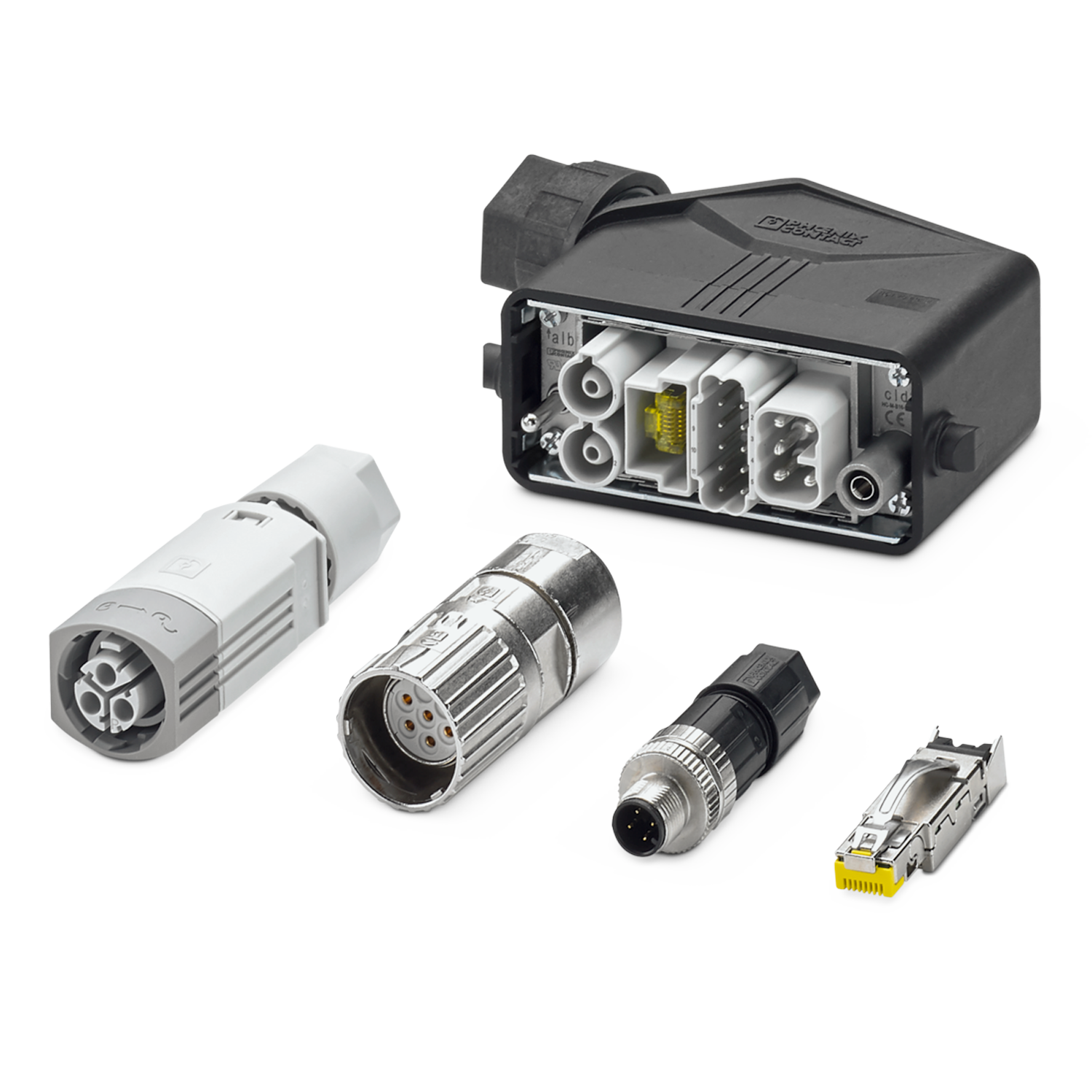

The result is a high-quality cable connector, in TH381 or TH387 version, and available in a 2.3 and 5-pole version with an IP66/IP68/IP69K protection rating. The connectors are equipped with neoprene cables (H05 and H07) with lengths of 0.5m, 1m, 2m and 5m, and sections of 0.75 mm2, 1mm2 and 1.5mm2.

Robust and long lasting

Cable and connector overmoulding prevents installation errors, accidental disconnections and tampering attempts. In addition, it protects internal components, strengthens protective qualities even in harsh conditions, solving a rather widespread problem at the root: the variation in the dimensions of the external insulation of cables, based on the humidity and temperature conditions of the environment.

The overmolded material is able to compensate for these variations, adapting perfectly to the cable and connector, ensuring constant performance and electrical continuity, as well as the guarantee of impenetrability to water and dust (IP68).

Further advantages of overmolding are:

Greater flexibility at the connection point between cable and connector, which is the weak point of the system

Protection against potential damage to terminals during handling and mating

Abrasion and impact resistance

Strain relief and reduced mechanical stress on cables and clamps

Standard applications and customized solutions

Overmoulded cable connectors are suitable for lighting applications, as they allow the quick connection of pre-configured systems such as floodlights, linear lighting bars and underfloor lighting systems. They are also suitable for industrial automation, where a typical application is the connection or powering of motors and servomotors through a series of connectors and wiring: in this case, the customer will simply have to determine the technical characteristics of the cables and connectors: our development and production team will take care of the rest.

Starting from the specifications provided by the customer, Techno also produces overmoulded connectors and custom sizes or non-linear shapes, such as angular connectors, or with special cables. The production of these solutions occurs after approval of a sample made with an internal 3D printer service , which is delivered to the customer so that he can verify the full compliance of the product with his needs.

Green soul

The resins used for overmoulded cable connectors are also sustainable, as they are made on a natural basis, completely recyclable, free from harmful fumes during molding, compliant with RoHS and REACH directives.

Check out the standard TH381 and TH387 connectors that the overmoulded leads are based on.